Toyota Venza: Yaw Rate Sensor Communication Stop Mode

DESCRIPTION

|

Detection Item |

Symptom |

Trouble Area |

|---|---|---|

|

Yaw Rate Sensor Communication Stop Mode |

|

|

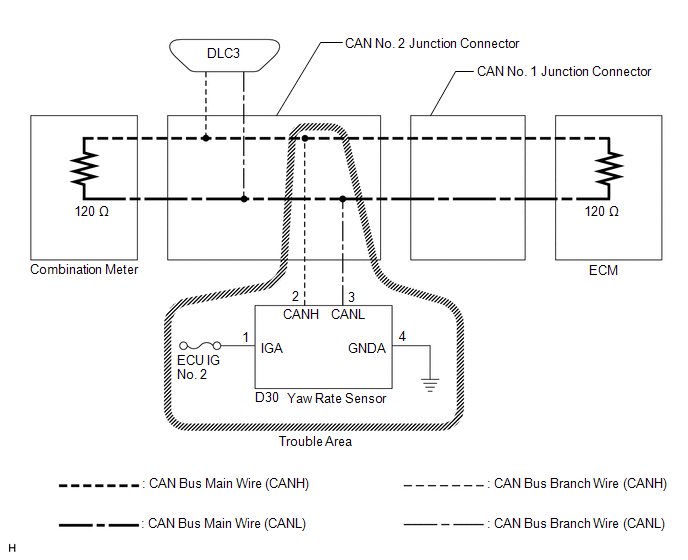

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Turn the ignition switch off before measuring the resistances between CAN bus main wires and between CAN bus branch wires.

- Turn the ignition switch off before inspecting CAN bus wires for a ground short.

- After the ignition switch is turned off, check that the key reminder warning system and light reminder warning system are not operating.

- Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches or the doors. If any doors need to be opened in order to check connectors, open the doors and leave them open.

HINT:

- Operating the ignition switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

- Even after DTCs are cleared, if a DTC is stored again after driving the vehicle for a while, the malfunction may be occurring due to vibration of the vehicle. In such a case, wiggling the ECUs or wire harness while performing the inspection below may help determine the cause of the malfunction.

PROCEDURE

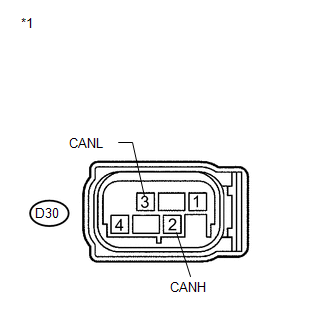

|

1. |

CHECK CAN BUS WIRE FOR DISCONNECTION (YAW RATE AND ACCELERATION SENSOR BRANCH WIRE) |

(a) Turn the ignition switch off.

|

(b) Disconnect the connector of the yaw rate and acceleration sensor. Text in Illustration

|

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

D30-2 (CANH) - D30-3 (CANL) |

Ignition switch off |

54 to 69 Ω |

| NG | .gif) |

REPAIR OR REPLACE CAN BUS BRANCH WIRE OR CONNECTOR (YAW RATE AND ACCELERATION SENSOR BRANCH WIRE) |

|

|

2. |

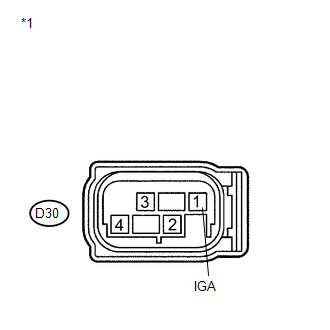

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL) |

|

(a) Turn the ignition switch to ON. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

D30-1 (IGA) - Body ground |

Ignition switch ON |

11 to 14 V |

|

*1 |

Front view of wire harness connector (to Yaw Rate Sensor) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

|

|

3. |

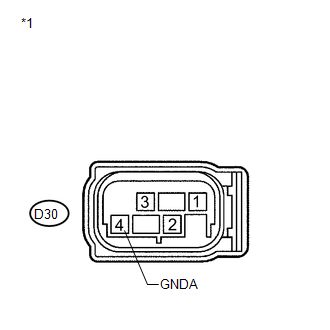

CHECK HARNESS AND CONNECTOR (GROUND TERMINAL) |

|

(a) Turn the ignition switch off. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D30-4 (GNDA) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Yaw Rate Sensor) |

| OK | .gif) |

REPLACE YAW RATE SENSOR |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (GROUND CIRCUIT) |

Steering Angle Sensor Communication Stop Mode

Steering Angle Sensor Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Steering Angle Sensor Communication Stop Mode

"Steering Angle Sensor" ...

ECM Communication Stop Mode

ECM Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

ECM Communication Stop Mode

"Engine" and "ECT" are not disp ...

Other materials about Toyota Venza:

Compass

The compass on the inside rear view mirror indicates the direction in which

the vehicle is heading.

- Operation

To turn the compass on or off, push and hold “AUTO” for longer than 3 seconds.

- Displays and directions

Calibrating the c ...

Internal Control Module EEPROM Error (P062F)

DESCRIPTION

The TCM monitors its internal operation and it will set this DTC when it detects

an internal malfunction.

DTC No.

DTC Detection Condition

Trouble Area

P062F

TCM internal error (EEPROM ...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / (desired system) / Trouble Codes.

(e) Check for DTCs.

2. CLEAR DTC

( ...

0.1554

.gif)