Toyota Venza: Wireless Door Lock Tuner Circuit Malfunction (B1242)

DESCRIPTION

The door control receiver receives signals from the transmitter and sends these signals to the main body ECU (driver side junction block assembly).

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1242 |

In diagnostic mode, an applicable RDA signal cannot be received within 2.4 seconds after a PRG signal has been output from the main body ECU (driver side junction block assembly). |

|

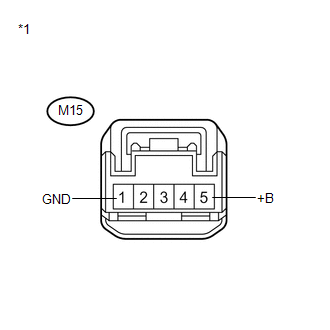

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - DOOR CONTROL RECEIVER) |

|

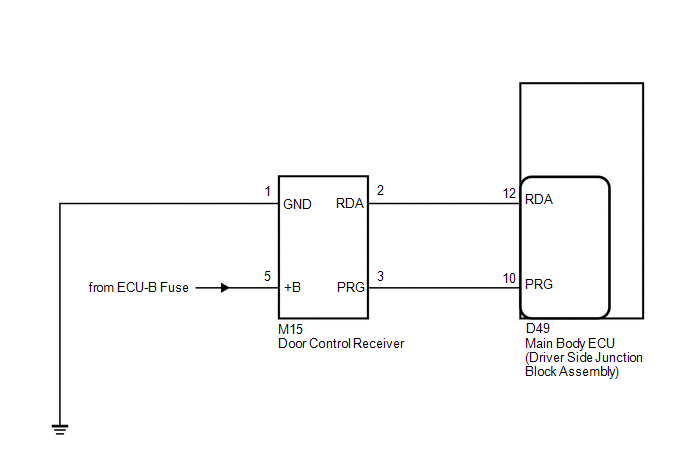

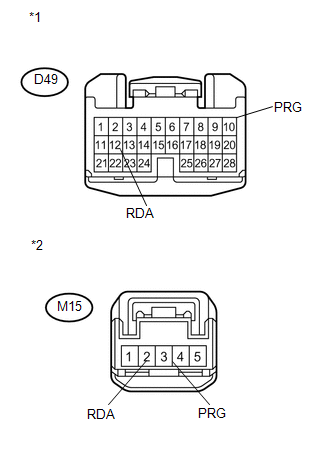

(a) Disconnect the D49 main body ECU connector and the M15 door control receiver connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D49-12 (RDA) - M15-2 (RDA) |

Always |

Below 1 Ω |

|

D49-12 (RDA) - Body ground |

Always |

10 kΩ or higher |

|

D49-10 (PRG) - M15-3 (PRG) |

Always |

Below 1 Ω |

|

D49-10 (PRG) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

|

*2 |

Front view of wire harness connector (to Door Control Receiver) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (BATTERY, BODY GROUND) |

|

(a) Measure the voltage and resistance according to the value(s) in the table below. Standard:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

REPLACE DOOR CONTROL RECEIVER |

(a) Temporarily replace the door lock control receiver with a new or known good

one (See page .gif) ).

).

|

|

4. |

REGISTER RECOGNITION CODE |

(a) Perform the Registration procedure (See page

.gif) ).

).

|

|

5. |

CONFIRM DTC |

(a) Clear the DTCs (See page .gif) ).

).

(b) Recheck for DTCs.

|

Result |

Proceed to |

|---|---|

|

DTC is not output |

A |

|

DTC is output |

B |

| A | .gif) |

END (DOOR CONTROL RECEIVER WAS DEFECTIVE) |

| B | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

Diagnostic Trouble Code Chart

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is output during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" in the ...

Only Wireless Control Function is Inoperative

Only Wireless Control Function is Inoperative

DESCRIPTION

The door control receiver receives signals from the transmitter and sends these

signals to the main body ECU. The main body ECU then controls all doors by sending

lock/unlock signals ...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Power Source Mode does not Change to ON (IG)

DESCRIPTION

When the engine switch is pushed with the electrical key in the cabin, the power

management control ECU receives signals to change the power source mode.

HINT:

To allow use of the Techstream to inspect the push-button start function when

the ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" column ...

0.1343

.gif)