Toyota Venza: Vehicle Speed Signal Malfunction (B2282)

DESCRIPTION

The power management control ECU receives vehicle speed information using 2 methods. It receives a speed signal from the meter ECU. It also receives speed information from the meter ECU via CAN. If the information sent using these 2 methods is inconsistent, this DTC will be stored.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2282 |

Speed information received by the power management control ECU via direct line and via CAN is inconsistent. |

|

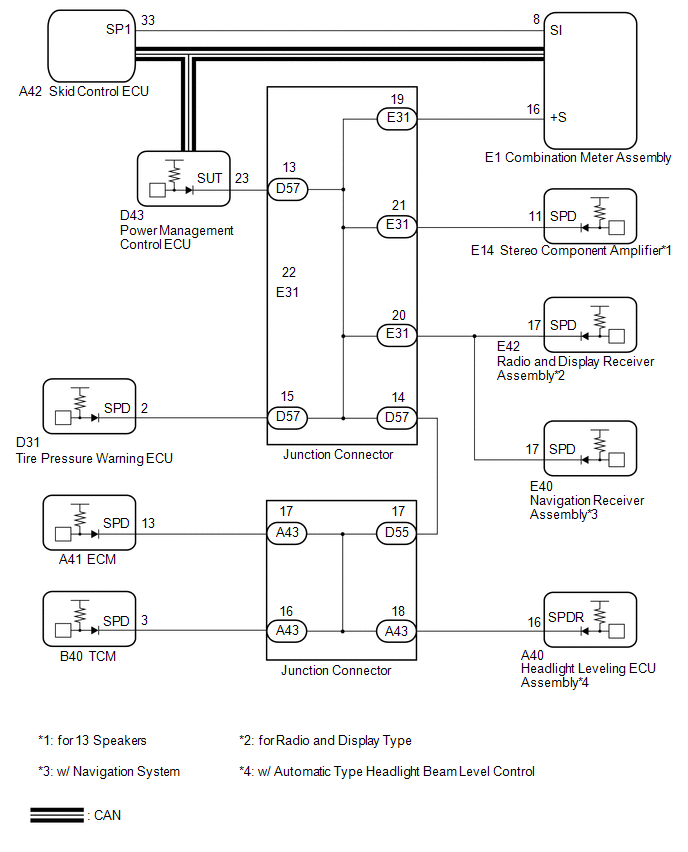

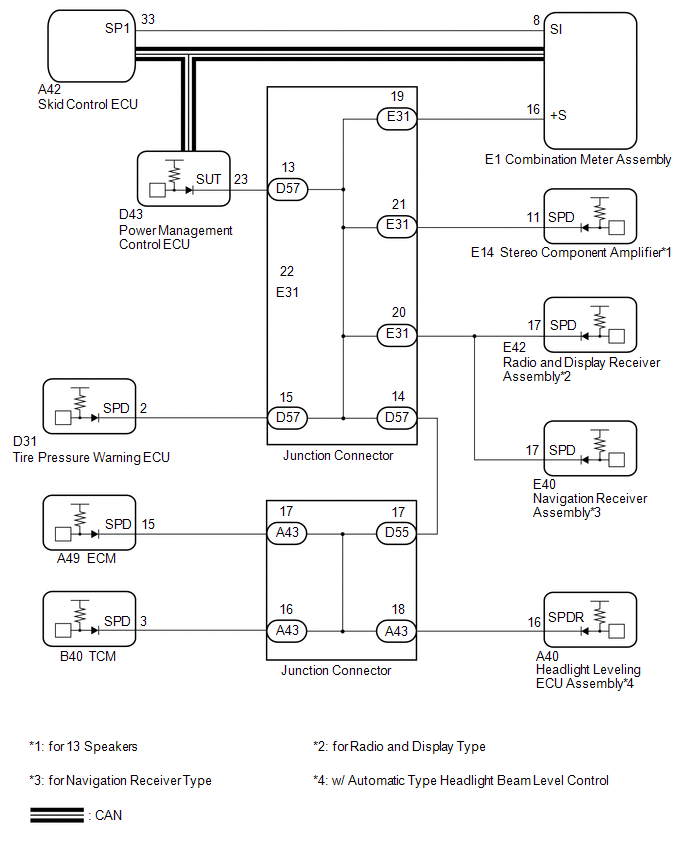

WIRING DIAGRAM

1. for 2GR-FE

2. for 1AR-FE

HINT:

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter. The signal is changed to a pulse signal at the transistor in the combination meter. Each ECU controls the respective system based on the pulse signal.

- If a short occurs in an ECU, all systems in the diagram above will not operate normally.

CAUTION / NOTICE / HINT

NOTICE:

- When the power management control ECU is replaced with a new one and the cable from the negative (-) battery terminal is connected, the power source mode becomes the on (IG) mode. When the battery is removed and reinstalled, the power source mode that was selected when the battery was removed is restored.

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if CAN communication DTCs are output.

HINT:

If any DTCs for CAN communication system malfunction are output, inspect those DTCs first.

OK:

CAN communication DTC is not output.

| NG | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

CHECK SPEEDOMETER OPERATION |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Data List.

(e) Check the Data List for proper functioning of the vehicle speed signal.

Combination Meter|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Vehicle Speed Meter |

Vehicle speed/Min.: 0, Max.: 255 |

Almost same as actual speed (When driving) |

- |

OK:

Vehicle speed displayed on the Techstream is almost the same as the actual vehicle speed measured using a speedometer tester (calibrated chassis dynamometer).

| NG | .gif) |

GO TO METER / GAUGE SYSTEM (Speedometer Malfunction) |

|

|

3. |

READ VALUE USING TECHSTREAM |

(a) Enter the following menus: Body Electrical / Power Source Control / Data List.

(b) Read the Data List according to the display on the Techstream.

Power Source Control|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Vehicle speed signal |

Vehicle speed signal/Stop or Run |

Sop: Vehicle stopped Run: Vehicle running |

- |

OK:

Stop (vehicle is stopped) and Run (vehicle is running) appear on the screen.

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

|

|

4. |

CHECK HARNESS AND CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

|

|

5. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

|

|

6. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - POWER MANAGEMENT CONTROL ECU) |

(a) Disconnect the E1 connector from the combination meter assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D43-23 (SUT) - E1-16 (+S) |

Always |

Below 1 Ω |

|

D43-23 (SUT) - Body ground |

Always |

10 kΩ or higher |

|

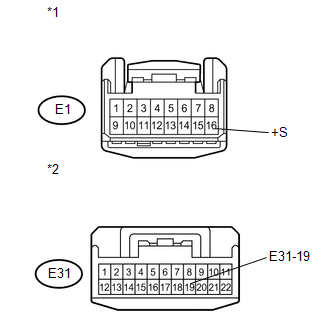

*1 |

Front view of wire harness connector (to Power Management Control ECU) |

*2 |

Front view of wire harness connector (to Combination Meter Assembly) |

| NG | .gif) |

GO TO STEP 8 |

|

|

7. |

INSPECT COMBINATION METER ASSEMBLY |

|

(a) Remove the combination meter (See page

|

|

(b) Reconnect the E1 connector to the combination meter assembly.

(c) Reconnect the D43 connector to the power management control ECU.

(d) Connect an oscilloscope to terminal E1-16 (+S) and body ground.

(e) Turn the engine switch on (IG).

(f) Turn the wheel slowly.

(g) Check the signal waveform according to the condition(s) in the table below.

|

Item |

Condition |

|---|---|

|

Tool setting |

5 V/DIV., 20 ms./DIV. |

|

Vehicle condition |

Driving at approx. 20 km/h (12 mph) |

OK:

The waveform is displayed as shown in the illustration.

Text in Illustration|

*1 |

Component with harness connected (Combination Meter Assembly) |

HINT:

When the system is functioning normally, one wheel revolution generates 4 pulses. As the vehicle speed increases, the width indicated by (A) in the illustration narrows.

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

GO TO METER / GAUGE SYSTEM (Speed Signal Circuit) |

|

8. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - JUNCTION CONNECTOR) |

|

(a) Disconnect the E31 connector from the junction connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E1-16 (+S) - E31-19 |

Always |

Below 1 Ω |

|

E1-16 (+S) - Body ground |

Always |

10 kΩ or higher |

|

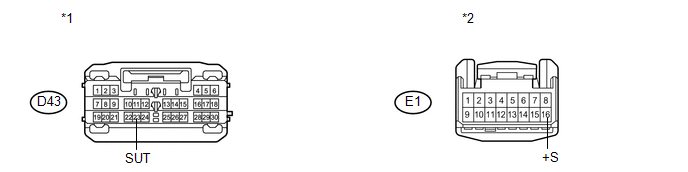

*1 |

Front view of wire harness connector (to Combination Meter Assembly) |

|

*2 |

Front view of wire harness connector (to Junction Connector) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (COMBINATION METER - JUNCTION CONNECTOR) |

|

|

9. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - JUNCTION CONNECTOR) |

(a) Disconnect the D57 connector from the junction connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

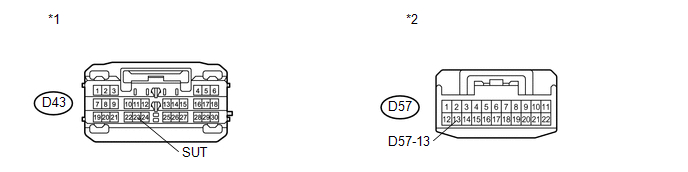

D43-23 (SUT) - D57-13 |

Always |

Below 1 Ω |

|

D43-23 (SUT) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Management Control ECU) |

*2 |

Front view of wire harness connector (to Junction Connector) |

| OK | .gif) |

REPLACE JUNCTION CONNECTOR |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - JUNCTION CONNECTOR) |

Runnable Signal Malfunction (B2286,P0335)

Runnable Signal Malfunction (B2286,P0335)

DESCRIPTION

The power management control ECU receives an engine speed signal and information

that indicates whether the engine is running or not. It receives the engine speed

signal from the ECM ...

Steering Lock Position Signal Circuit Malfunction (B2285)

Steering Lock Position Signal Circuit Malfunction (B2285)

DESCRIPTION

This DTC is stored when serial communication signals and LIN communication signals

in the circuit between the power management control ECU and steering lock actuator

assembly (steerin ...

Other materials about Toyota Venza:

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM (REFERENCE)

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Record th ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Be sure to follow the correct removal and installation procedures of the rear

airbag sensor.

PROCEDURE

1. INSPECT REAR AIRBAG SENSOR (VEHICLE NOT INVOLVED IN COLLISION)

(a) Perform a diagnostic sys ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR NO. 2 SPEAKER ASSEMBLY (for 13 Speakers)

(a) Install the rear No. 2 speaker assembly with the 2 screws.

(b) Engage the clamp.

2. INSTALL REAR SPEAKER BRACKET ...

0.1517

.gif)

.png)