Toyota Venza: Speed Signal Circuit

DESCRIPTION

The headlight leveling ECU assembly receives the vehicle speed signal from the combination meter assembly.

HINT:

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter. The signal is changed to a pulse signal at the transistor in the combination meter. Each ECU controls the respective system based on the pulse signal.

- If a short occurs in any of the ECUs or in the wire harness connected to an ECU, all systems in the diagram below will not operate normally.

WIRING DIAGRAM

1. for 2GR-FE

.png)

2. for 1AR-FE

.png)

PROCEDURE

|

1. |

CHECK COMBINATION METER SYSTEM |

(a) The circuits that send vehicle speed signals to this system are inspected

in the meter section (See page .gif) ).

).

(b) During inspection for the meter system, if there is an instruction that indicates to go back to inspections for the lighting system, proceed to the next step.

|

|

2. |

CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU ASSEMBLY - COMBINATION METER ASSEMBLY) |

|

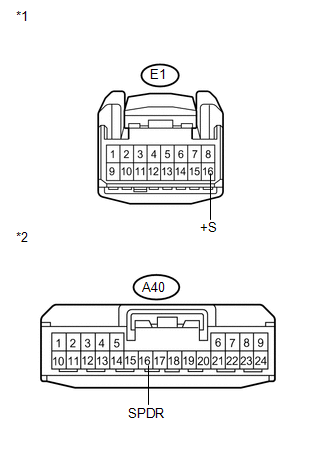

(a) Disconnect the E1 combination meter assembly connector. |

|

(b) Disconnect the A40 headlight leveling ECU assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A40-16 (SPDR) - E1-16 (+S) |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Combination Meter Assembly) |

|

*2 |

Front view of wire harness connector (to Headlight Leveling ECU Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (WIPER RELAY - COMBINATION METER) |

|

|

3. |

INSPECT COMBINATION METER ASSEMBLY (OUTPUT WAVEFORM) |

|

(a) Check the output waveform. (1) Remove the combination meter assembly with the connector still connected. (2) Connect an oscilloscope to terminal E1-16 (+S) and body ground. (3) Turn the ignition switch to ON. (4) Check the signal waveform according to the condition(s) in the table below.

OK: The waveform is displayed as shown in the illustration. Text in Illustration

HINT: When the system is functioning normally, one wheel revolution generates 4 pulses. As the vehicle speed increases, the width indicated by (A) in the illustration narrows. |

|

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

Indicator Circuit

Indicator Circuit

DESCRIPTION

The headlight beam level control system indicator light in the combination meter

assembly comes on for approximately 3 seconds when the ignition switch is turned

to ON. The indicator ...

Inner Rear View Mirror Power Source Circuit

Inner Rear View Mirror Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the inner

rear view mirror assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for ci ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

(b) Install the generator rotor assembly to the drive end frame.

2. INSTALL GENERATOR CL ...

Pressure Control Solenoid "A" Electrical (Shift Solenoid Valve SL1) (P0748)

DESCRIPTION

Changing from 1st to 6th is performed by the TCM turning shift solenoid valves

SL1, SL2, SL3, SL4 and SL on and off. If an open or short circuit occurs in any

of the shift solenoid valves, the TCM controls the remaining normal shift solenoid

...

0.1199

.gif)

.png)