Toyota Venza: Security Indicator Light Circuit

DESCRIPTION

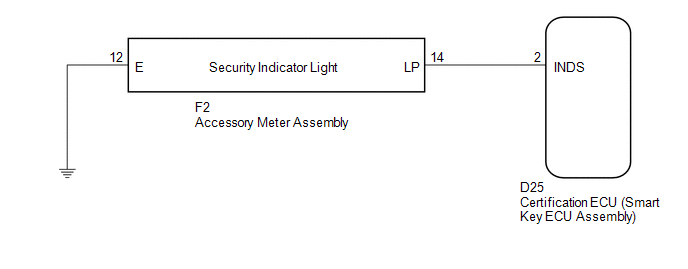

The security indicator light blinks continuously due to a continuous signal received from the certification ECU (smart key ECU assembly) while the engine immobiliser is set.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the certification ECU (smart key ECU assembly) is replaced, register the key

and ECU communication ID (See page .gif) ).

).

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Smart Key (Certification ECU (Smart Key ECU Assembly))|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Security Indicator |

Security indicator light |

ON or OFF |

- |

OK:

The security indicator light turns on and off according to operation via the Techstream.

| OK | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - ACCESSORY METER ASSEMBLY) |

(a) Disconnect the certification ECU (smart key ECU assembly) connector.

|

(b) Disconnect the accessory meter assembly connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D25-2 (INDS) - F2-14 (LP) |

Always |

Below 1 Ω |

|

D25-2 (INDS) - Body ground |

Always |

10 kΩ or higher |

|

F2-14 (LP) - Body ground |

Always |

10 kΩ or higher |

|

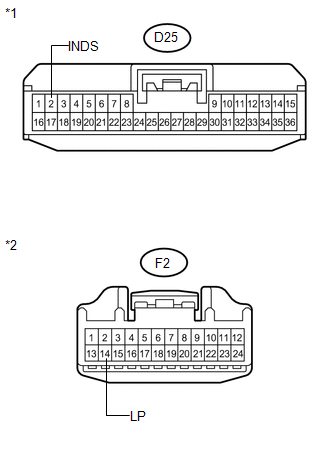

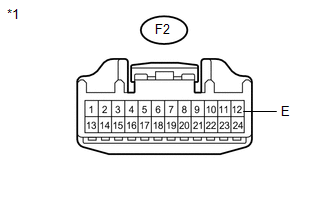

*1 |

Front view of wire harness connector (to Certification ECU (Smart Key ECU Assembly)) |

|

*2 |

Front view of wire harness connector (to Accessory Meter Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (ACCESSORY METER ASSEMBLY - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Antenna Coil Open / Short (B2784)

Antenna Coil Open / Short (B2784)

DESCRIPTION

This DTC is stored when there is an open or short in the transponder key coil

(built into the engine switch).

DTC No.

DTC Detection Condition

Trouble A ...

Other materials about Toyota Venza:

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure is for the LH side.

If the sensor rotor needs to be replaced, replace it together with the

front drive shaft assembly.

...

Emission inspection and maintenance (I/M) programs

Some states have vehicle emission inspection programs which include OBD (On

Board Diagnostics) checks. The OBD system monitors the operation of the emission

control system.

- If the malfunction indicator lamp comes on

The OBD system determines that ...

Rear Occupant Classification Sensor RH Collision Detection (B1788)

DESCRIPTION

DTC B1788 is output when the occupant classification ECU receives a collision

detection signal sent by the rear occupant classification sensor RH if an accident

occurs.

DTC B1788 is also output when the front seat assembly RH is subjected to ...

0.1588

.gif)