Toyota Venza: Repair

REPAIR

PROCEDURE

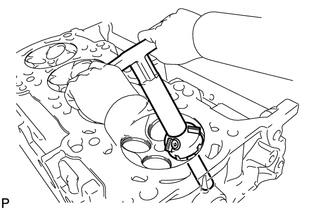

1. REPAIR INTAKE VALVE SEAT

NOTICE:

- Repair the seat while checking the seating position.

- Keep the lip free of foreign matter.

- Take off the cutter gradually to make the intake valve seat smooth.

|

(a) Using a 45° cutter, resurface the valve seat so that the valve seat width is more than the specification. |

|

|

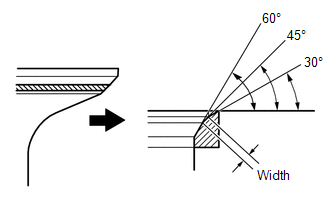

(b) Using 30° and 60° cutters, correct the valve seat so that the valve contacts the entire circumference of the seat. The contact should be in the center of the valve seat, and the valve seat width should be maintained within the specified range around the entire circumference of the seat. Standard width: 1.0 to 1.4 mm (0.0394 to 0.0551 in.) |

|

(c) Hand-lap the valve and valve seat with an abrasive compound.

(d) Check the valve seating position.

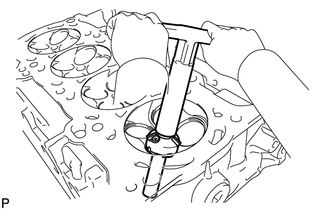

2. REPAIR EXHAUST VALVE SEAT

NOTICE:

- Repair the seat while checking the seating position.

- Keep the lip free of foreign matter.

- Take off the cutter gradually to make the exhaust valve seat smooth.

|

(a) Using a 45° cutter, resurface the valve seat so that the valve seat width is more than the specification. |

|

|

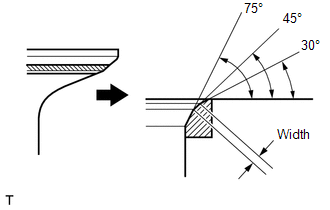

(b) Using 30° and 75° cutters, correct the valve seat so that the valve contacts the entire circumference of the seat. The contact should be in the center of the valve seat, and the valve seat width should be maintained within the specified range around the entire circumference of the seat. Standard width: 1.2 to 1.6 mm (0.0472 to 0.0630 in.) |

|

(c) Hand-lap the valve and valve seat with an abrasive compound.

(d) Check the valve seating position.

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the cylinder head sub-assembly

(See page ).

PROCEDURE

1. INSTALL SPARK PLUG TUBE

HINT:

Wh ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT TIE ROD ASSEMBLY LH

(a) Secure the tie rod assembly LH in a vise.

(b) Install the nut to the stud bolt.

(c) Flip the ball joint back and forth 5 times.

(d) Set a to ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Engine Control System Malfunction (C1201/51)

DESCRIPTION

If a malfunction in the engine control system is detected, the operations of

VSC and TRAC are prohibited by the fail-safe function. When the signals from the

engine are input normally, the fail-safe is cancelled and the DTC is not stored.

...

0.1295