Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

2. REMOVE INLET NO. 2 AIR CLEANER

.gif)

3. REMOVE AIR CLEANER CAP WITH HOSE

.gif)

4. REMOVE AIR CLEANER CASE

.gif)

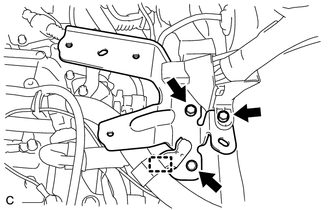

5. REMOVE AIR CLEANER BRACKET

|

(a) Separate the wire harness clamp. |

|

(b) Remove the 3 bolts and air cleaner bracket.

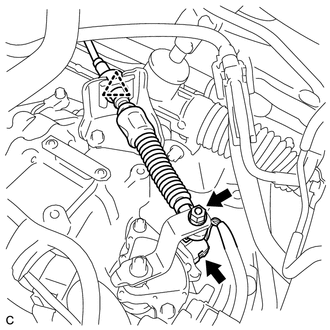

6. REMOVE PARK/NEUTRAL POSITION SWITCH ASSEMBLY

|

(a) Remove the clip from the transmission cable bracket. |

|

(b) Remove the nut and transmission control cable from the transmission control shaft lever.

(c) Disconnect the connector from the park/neutral position switch.

|

(d) Remove the nut, washer and transmission control shaft lever from the control shaft. |

|

|

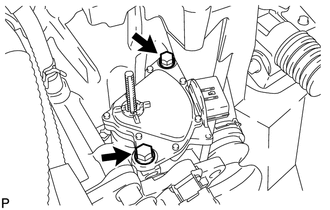

(e) Remove the 2 bolts and park/neutral position switch from the control shaft. NOTICE: Before removing the park/neutral position switch, remove any dirt or rust on the installation portion of the control shaft. Be sure to remove the switch straight along the shaft while being careful not to deform the plate spring that supports the shaft. If the plate spring is deformed, the park/neutral position switch cannot be reinstalled correctly. |

|

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY OPERATION

(a) Apply the parking brake.

(b) Turn the ignition switch to ON.

(c) Depress the brake pedal and check t ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below

when the shift lever is moved to each po ...

Other materials about Toyota Venza:

Fog light switch

The fog lights improve visibility in difficult driving conditions, such as

in rain or fog. The fog lights can be used when the headlights are on low beam.

Type A

1. Off

2. On

Type B

1. Off

2. On

Wiper intervals can be adjusted for intermittent ...

Low Battery Positive Voltage or Abnormally High Battery Positive Voltage (C1241/41)

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU

(housed in the actuator assembly) stores this DTC and the fail-safe function prohibits

ABS operation.

This DTC is stored when the IG1 terminal voltage deviates fro ...

PBD Pulse Sensor Malfunction (B2222)

DESCRIPTION

A pulse sensor is built into the power back door ECU (power back door

motor unit) to detect foreign objects and the back door position. The pulse

sensor monitors the operating speed of the back door to detect foreign objects.

Th ...

0.1724

.png)