Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from the booster by depressing the brake pedal several times. Then remove the brake master cylinder from the brake booster.

PROCEDURE

1. DRAIN BRAKE FLUID

NOTICE:

If brake fluid leaks onto any painted surface, immediately wash it off.

2. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (for 1AR-FE)

.gif)

3. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (for 2GR-FE)

.gif)

4. REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

5. REMOVE BRAKE MASTER CYLINDER SUB-ASSEMBLY

|

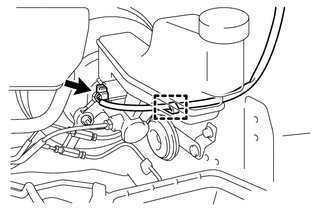

(a) Disconnect the connector and disengage the clamp. |

|

|

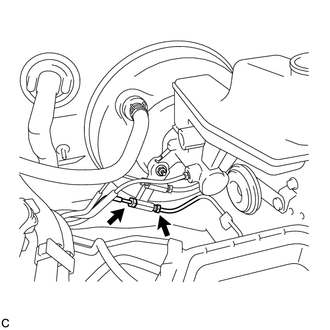

(b) Using a union nut wrench, disconnect the 2 brake lines from the front brake tube way. NOTICE:

|

|

|

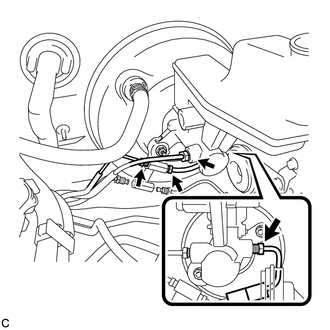

(c) Using a union nut wrench, disconnect the 2 brake lines and remove the No. 1 front brake tube from the brake master cylinder sub-assembly. NOTICE:

|

|

|

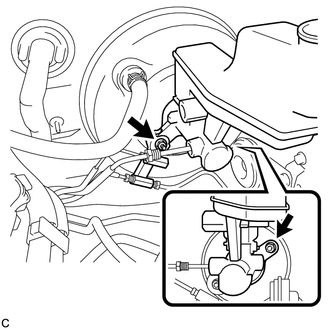

(d) Remove the 2 nuts, front brake tube way and brake master cylinder sub-assembly from the brake booster assembly. NOTICE:

|

|

(e) Remove the O-ring from the brake master cylinder sub-assembly.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY

(a) Mount the brake master cylinder sub-assembly in a vise.

NOTICE:

Place aluminum plates on the vise to prevent damage to ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

NOTICE:

When install a new brake master cylinder sub-assembly, remove the protectors

from the piston and outlet ports.

(a) I ...

Other materials about Toyota Venza:

Daytime Running Light Relay Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the daytime

running lights.

WIRING DIAGRAM

1. for Halogen Headlight

2. for HID Headlight

PROCEDURE

1.

PERFORM ACTIVE TEST USING TECHSTREAM

...

Front Left Sensor Malfunction (C1AE1)

DESCRIPTION

The No. 1 ultrasonic sensor (front left sensor) is installed on the front bumper.

The ECU detects obstacles based on signals received from the No. 1 ultrasonic sensor

(front left sensor). If the No. 1 ultrasonic sensor (front left sensor) has ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the window defogger system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

0.1564