Toyota Venza: Removal

REMOVAL

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

.gif)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. REMOVE FRONT WHEEL RH

4. REMOVE NO. 1 ENGINE UNDER COVER

5. REMOVE NO. 2 ENGINE UNDER COVER

6. SEPARATE FRONT FENDER LINER RH

7. REMOVE FRONT FENDER APRON RH

8. REMOVE V-RIBBED BELT

.gif)

9. DRAIN ENGINE COOLANT

.gif)

10. REMOVE V-BANK COVER SUB-ASSEMBLY

.gif)

11. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

12. REMOVE RADIATOR GRILLE

.gif)

13. REMOVE INLET NO. 2 AIR CLEANER

.gif)

14. REMOVE AIR CLEANER CAP WITH HOSE

.gif)

15. REMOVE AIR CLEANER CASE

.gif)

16. REMOVE BATTERY

.gif)

17. REMOVE INLET NO. 1 AIR CLEANER

.gif)

18. REMOVE LOW PITCHED HORN ASSEMBLY

.gif)

19. REMOVE HIGH PITCHED HORN ASSEMBLY

.gif)

20. REMOVE HOOD LOCK ASSEMBLY (w/o Engine Hood Courtesy Switch)

.gif)

21. REMOVE HOOD LOCK ASSEMBLY (w/ Engine Hood Courtesy Switch)

.gif)

22. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

.gif)

23. DISCONNECT OUTLET RESERVE TANK HOSE

.gif)

24. DISCONNECT NO. 1 RADIATOR HOSE

.gif)

25. REMOVE NO. 2 RADIATOR HOSE

.gif)

26. DISCONNECT INLET OIL COOLER HOSE

.gif)

27. DISCONNECT OUTLET OIL COOLER HOSE

.gif)

28. REMOVE UPPER RADIATOR SUPPORT

.gif)

29. DISCONNECT COOLER REFRIGERANT DISCHARGE HOSE

.gif)

30. DISCONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

.gif)

31. REMOVE COOLER CONDENSER ASSEMBLY

.gif)

32. REMOVE RADIATOR ASSEMBLY AND FAN ASSEMBLY WITH MOTOR

.gif)

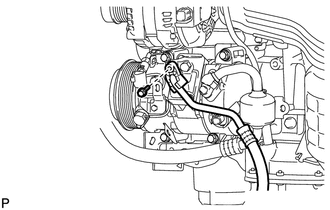

33. DISCONNECT COOLER REFRIGERANT DISCHARGE HOSE

|

(a) Remove the bolt and disconnect the cooler refrigerant discharge hose from the compressor and magnetic clutch. |

|

(b) Remove the O-ring from the discharge hose.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

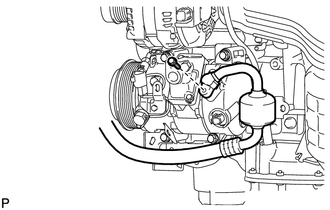

34. DISCONNECT SUCTION HOSE SUB-ASSEMBLY

|

(a) Remove the bolt and disconnect the suction hose sub-assembly from the compressor and magnetic clutch. |

|

(b) Remove the O-ring from the suction hose sub-assembly.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

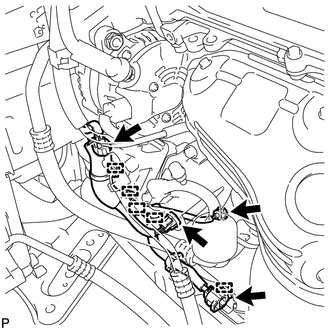

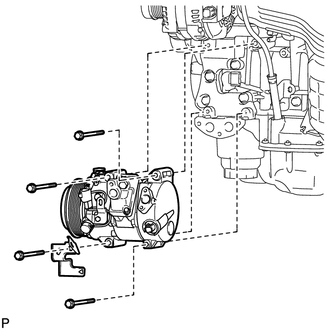

35. REMOVE COMPRESSOR AND MAGNETIC CLUTCH

|

(a) Disengage each clamp. |

|

(b) Disconnect each connector.

|

(c) Remove the 4 bolts, bracket, and the compressor and magnetic clutch. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC CLUTCH ASSEMBLY

(a) Place the compressor and magnetic clutch in a vise.

(b) Using SST, hold the m ...

Other materials about Toyota Venza:

Security Indicator Light Circuit

DESCRIPTION

The security indicator light blinks continuously due to a continuous signal received

from the certification ECU (smart key ECU assembly) while the engine immobiliser

is set.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the certifica ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

When disconnecting the steering intermediate shaft assembly and pinion shaft

of steering gear assembly, be sure to place matchmarks before servicing.

PROCEDURE

1. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

2. SECUR ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TRANSFER AND TRANSAXLE SETTING STUD BOLT

(a) Remove the 4 transfer and transaxle setting stud bolts.

2. REMOVE NO. 2 TRANSFER CASE PLUG

(a) Remove the No. ...

0.1585