Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE

(a) Remove the fuel suction tube assembly with pump and gauge (See page

.gif) ).

).

2. REMOVE FUEL SENDER GAUGE

.gif)

3. REMOVE FUEL FILTER ASSEMBLY

|

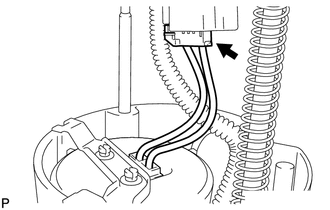

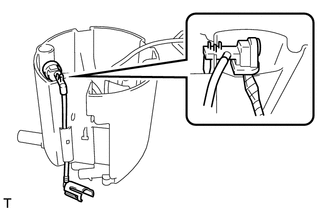

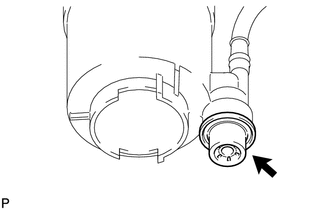

(a) Disconnect the fuel pump connector from the fuel suction plate. NOTICE: Do not damage the wire harness. |

|

|

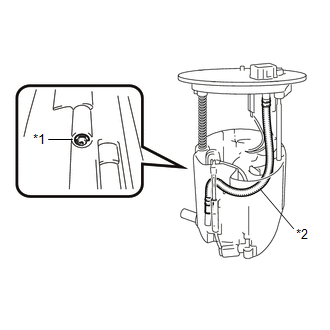

(b) Using needle nose pliers, remove the E-ring. Text in Illustration

NOTICE: Do not disconnect the tube shown in the illustration when disassembling the fuel suction tube assembly with pump and gauge. Doing so will cause reassembly of the fuel suction tube assembly with pump and gauge to be impossible as the tube is welded to the plate. |

|

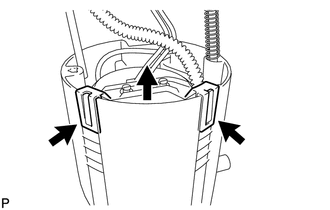

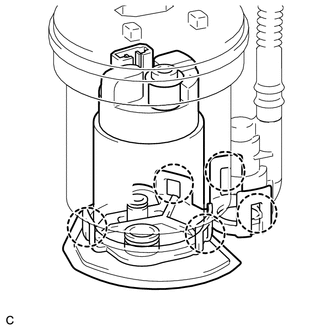

(c) Separate the fuel suction plate and remove the spring from the sub-tank.

|

(d) Detach the 2 claws and remove the fuel filter from the sub-tank. |

|

|

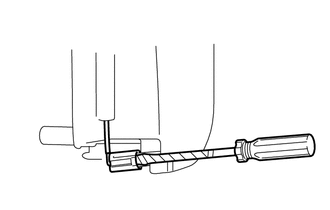

(e) Using a screwdriver with the tip taped, detach the claw of the jet pump nozzle. |

|

|

(f) Using a screwdriver with the tip taped, remove the jet pump from the sub-tank. |

|

|

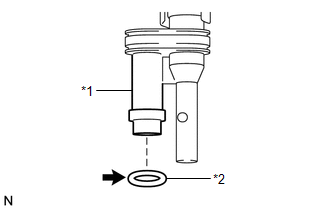

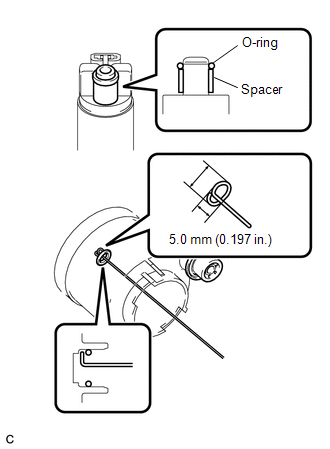

(g) Remove the O-ring from the jet pump. Text in Illustration

|

|

4. REMOVE FUEL PUMP ASSEMBLY WITH FILTER

|

(a) Detach the 5 claws on the filter and remove the fuel pump from the fuel filter. NOTICE:

HINT: If the fuel filter assembly is to be replaced, replace the fuel suction plate sub-assembly. |

|

|

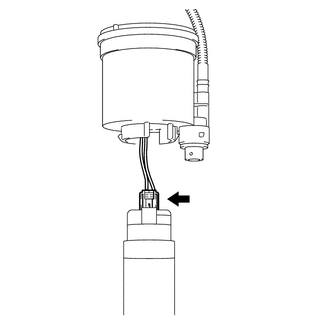

(b) Disconnect the fuel pump connector from the fuel pump and then remove the fuel pump harness. |

|

|

(c) Remove the O-ring and spacer from the fuel pump. NOTICE: Be careful not to damage the sealing surface. HINT: If the O-ring still remains in the fuel filter, remove it using a wire tip (φ1 mm) that is formed as shown in the illustration. |

|

5. REMOVE FUEL PRESSURE REGULATOR ASSEMBLY

|

(a) Remove the fuel pressure regulator from the fuel filter. |

|

(b) Remove the 2 O-rings.

Components

Components

COMPONENTS

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline to 2 new O-rings, and install them

onto the fuel pressure regulator.

Text in ...

Other materials about Toyota Venza:

Terminals Of Ecu

TERMINALS OF ECU

1. STEERING LOCK ECU (STEERING LOCK ACTUATOR ASSEMBLY)

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

Specified Condition

D17-1 (GND) - Body ground

...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. READ DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very usefu ...

Combination Meter ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Combination Meter ECU Communication Stop Mode

"Combination Meter" is not displayed on "CAN Bus Check" screen

of t ...

0.1236