Toyota Venza: Removal

REMOVAL

PROCEDURE

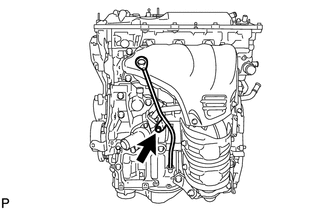

1. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

|

(a) Remove the engine oil level dipstick. |

|

(b) Remove the bolt and engine oil level dipstick guide.

(c) Remove the O-ring from the engine oil level dipstick guide.

2. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

.gif)

3. REMOVE MANIFOLD STAY

.gif)

4. REMOVE NO. 2 MANIFOLD STAY

.gif)

5. REMOVE EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

.gif)

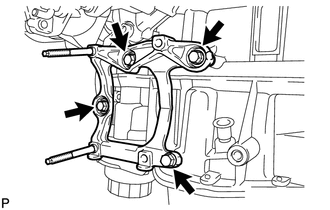

6. REMOVE NO. 1 COMPRESSOR MOUNTING BRACKET

|

(a) Remove the 4 bolts and bracket. |

|

7. REMOVE THROTTLE BODY ASSEMBLY

.gif)

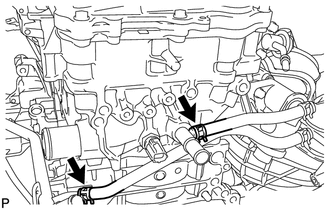

8. REMOVE WATER BY-PASS HOSE

|

(a) Remove the No. 1 and No. 2 water by-pass hoses. |

|

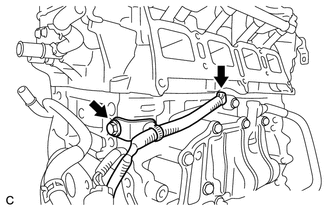

9. DISCONNECT NO. 2 VENTILATION HOSE

.gif)

10. REMOVE INTAKE MANIFOLD

.gif)

11. REMOVE SENSOR WIRE

|

(a) Disconnect the knock control sensor connector. |

|

(b) Remove the bolt and sensor wire.

12. REMOVE KNOCK CONTROL SENSOR

.gif)

13. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

.gif)

14. REMOVE ENGINE COOLANT TEMPERATURE SENSOR

.gif)

15. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

.gif)

16. REMOVE IGNITION COIL ASSEMBLY

.gif)

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE ENGINE COVER JOINT

(a) Remove the 3 joints.

2. REMOVE SPARK PLUG

3. REMOVE CAMSHAFT TIMING OIL CONTROL ...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

2. REMOVE STATOR SHAFT ASSEMBLY

(a) Using a "TORX" wrench (T30), remove the 16 bolts and stator shaft

assembly from the oil pump body.

NOTICE:

Keep ...

Precaution

PRECAUTION

1. BASIC REPAIR HINT

(a) HINTS ON OPERATIONS

1

Attire

Always wear a clean uniform.

A hat and safety shoes must be worn.

2

Vehicle protection

Prep ...

Power Back Door Control Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT POWER BACK DOOR OPENER / CLOSER SWITCH

(a) Measure the resistance of the switch.

Standard resistance:

Tester Connection

Condition

S ...

0.1209