Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR CONSOLE ARMREST ASSEMBLY

(a) Temporarily install the rear console armrest assembly.

|

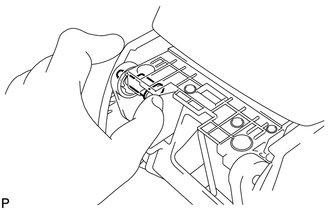

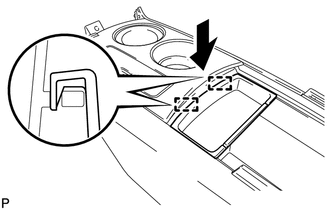

(b) Push in the box door hinge shafts by hand as far as possible. HINT:

|

|

|

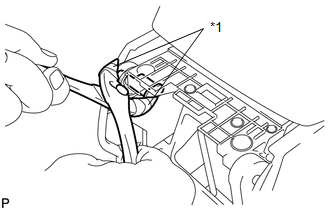

(c) Using pliers, push in the box door hinge shafts completely. Text in Illustration

HINT:

|

|

|

(d) Install the rear console armrest assembly with the 2 E-rings. |

|

2. INSTALL REAR CONSOLE END PANEL SUB-ASSEMBLY

|

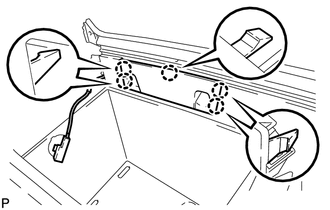

(a) Engage the 4 clips to install the rear console end panel sub-assembly. |

|

3. INSTALL CENTER POWER OUTLET SOCKET COVER

.gif)

4. INSTALL CENTER POWER POINT SOCKET ASSEMBLY

.gif)

5. INSTALL CONSOLE BOX ILLUMINATION LIGHT ASSEMBLY

.gif)

6. INSTALL CONSOLE BOX WIRE

|

(a) Connect the connectors to install the console box wire. |

|

7. INSTALL CONSOLE MOUNTING RETAINER ASSEMBLY

|

(a) Engage the 5 claws to install the console mounting retainer assembly. |

|

8. INSTALL NO. 2 CONSOLE BOX DUCT

|

(a) Install the No. 2 console box duct with the 2 screws. |

|

9. INSTALL REAR CONSOLE UPPER PANEL SUB-ASSEMBLY

|

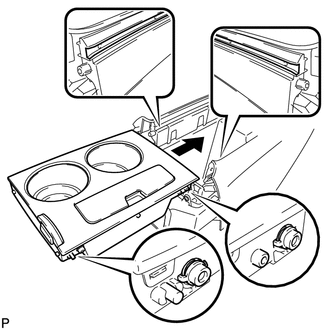

(a) Aligning the inside groove of the front console box assembly with the rear console upper panel hinge, slide the rear console upper panel sub-assembly and install it. |

|

10. INSTALL STEREO JACK ADAPTER ASSEMBLY

.gif)

11. INSTALL FRONT CONSOLE BOX COVER

|

(a) Engage the 2 claws. |

|

(b) Install the front console box cover with the 3 screws.

(c) Engage the clamp.

12. INSTALL CONSOLE BOX POCKET

|

(a) Engage the 2 guides to install the console box pocket. |

|

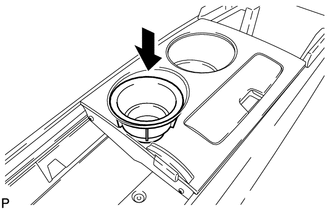

13. INSTALL INSTRUMENT PANEL CUP HOLDER DAMPER

|

(a) Install the instrument panel cup holder damper. |

|

14. INSTALL NO. 1 CONSOLE BOX CARPET

|

(a) Install the No. 1 console box carpet. |

|

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL CONSOLE BOX ASSEMBLY

(a) Connect the connectors.

(b) Engage the 2 claws.

(c) Install the scr ...

Other materials about Toyota Venza:

Precaution

PRECAUTION

NOTICE:

When the ignition switch is turned off and the engine temperature is

high, the cooling fans may operate for a maximum of 6 minutes.

After turning the ignition switch off, keep hands and objects away from

the fans when t ...

Towing related terms

- GCWR (Gross Combination Weight Rating)

► 2GR-FE engine (Without towing package)

and 1AR-FE engine

The maximum allowable gross combination weight. The gross combination weight

is the sum of the total vehicle weight (including the occupants ...

Head restraints

Head restraints are provided for all seats.

► Front and rear outboard seats

Vertical adjustment 1. Up

Pull the head restraint up.

2. Down

Push the head restraints down while pressing the lock release button.

► Rear center seat (fabric seat) ...

0.159

.png)

.png)

.png)

.png)

.png)

.png)