Toyota Venza: Rear Wiper Rubber

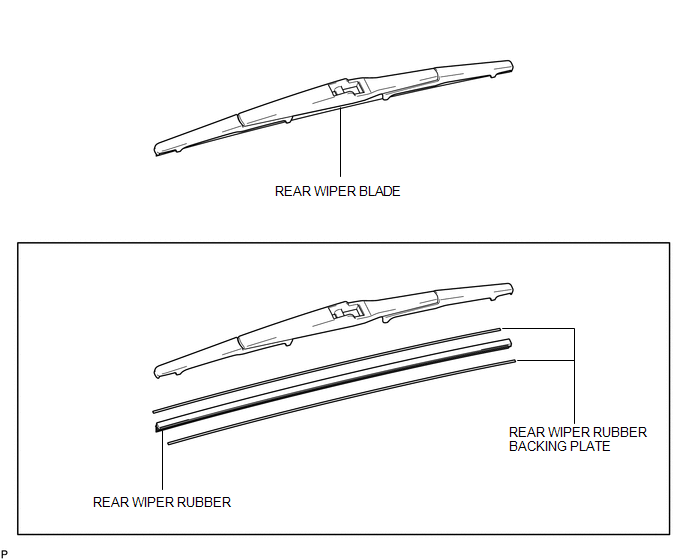

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE REAR WIPER BLADE

|

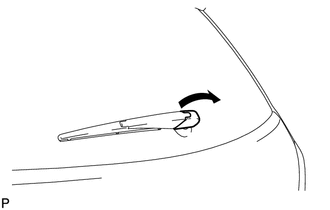

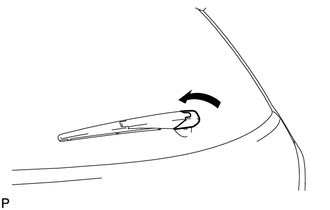

(a) Disconnect the rear wiper arm head cap. |

|

|

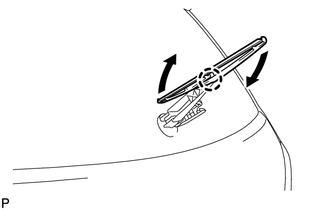

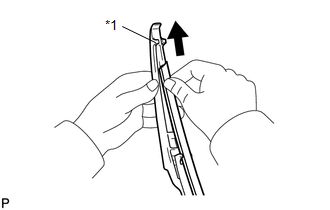

(b) Raise the wiper blade to the position where the claw detaches with a click sound, as shown in the illustration. NOTICE: Be careful not to damage the claw. |

|

|

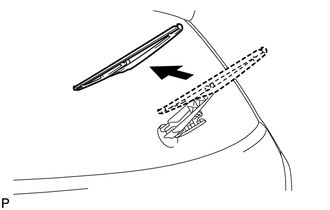

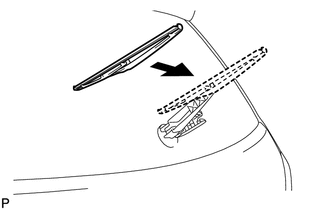

(c) Pull the wiper blade straight toward the left side of the vehicle to remove it from the wiper arm. NOTICE: Do not lower the wiper arm with the wiper blade removed. The arm tip may damage the back door glass surface. |

|

2. REMOVE REAR WIPER RUBBER

|

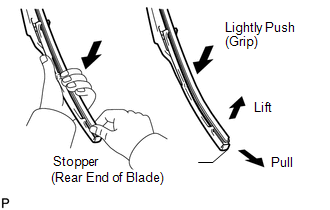

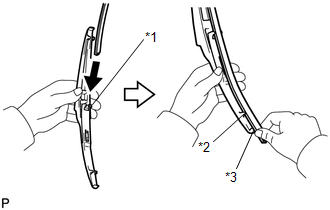

(a) Lift and pull the end of the wiper rubber protrusion from the blade stopper as shown in the illustration. NOTICE: Do not forcibly pull out the wiper rubber. The backing plates will be deformed or the blade claws will be damaged. HINT: Lightly pushing the rubber in the middle will allow it to be removed more easily. |

|

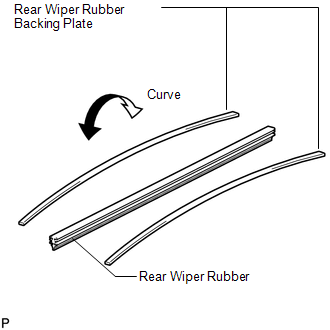

(b) Remove the rear wiper rubber backing plates.

3. INSTALL REAR WIPER RUBBER

|

(a) Install the rear wiper rubber backing plates as shown in the illustration. NOTICE: Install the backing plates facing the correct direction. |

|

(b) Insert the wiper rubber from the front end of the wiper blade to the rear end through the second claw.

|

(c) After pushing the wiper rubber through the rear end claw, allow it to stick out from the rear end stopper. Text in Illustration

|

|

|

(d) Slide the wiper rubber through the front end claw. Text in Illustration

|

|

4. INSTALL REAR WIPER BLADE

|

(a) Push the wiper blade straight toward the right side of the vehicle to install it to the wiper arm. NOTICE: Be careful not to damage the claw. |

|

|

(b) Connect the rear wiper head cap. |

|

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Install the rear wiper motor and bracket assembly with the 3 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in ...

Washer Level Warning Switch

Washer Level Warning Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT LEVEL WARNING SWITCH ASSEMBLY

HINT:

The following check should be performed with the windshield washer motor ...

Other materials about Toyota Venza:

Camshaft Position "A" Actuator Circuit (Bank 1) (P0010)

DESCRIPTION

The Variable Valve Timing (VVT) system adjusts the intake valve timing to improve

driveability. The engine oil pressure turns the VVT controller to adjust the valve

timing.

The camshaft timing oil control valve assembly is a solenoid valve an ...

Air Fuel Ratio Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2. REMOVE COOL AIR INTAKE DUCT SEAL

3. REMOVE INLET AIR CLEANER ASSEMBLY

4. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

5. REMOV ...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR WHEELS

2. REMOVE CENTER EXHAUST PIPE ASSEMBLY

(a) Remove the center exhaust pipe assembly.

HINT:

Refer to the instructions for Removal of the exhaust pipe (See page

for 2GR-FE,

for 1AR-FE).

3. REMOVE LOWER NO. 1 EXH ...

0.1171