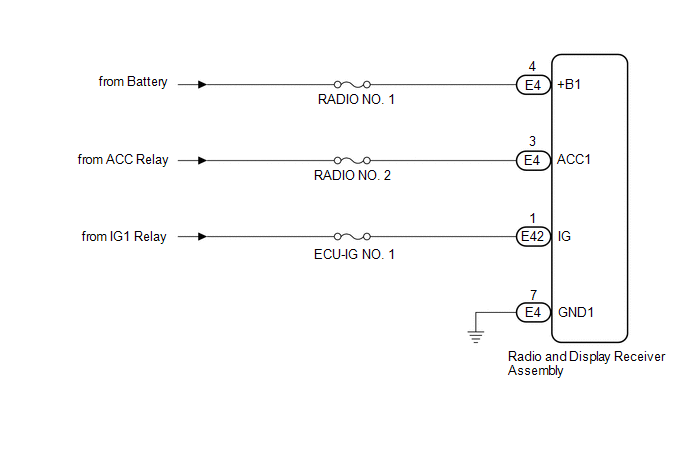

Toyota Venza: Radio Receiver Power Source Circuit

DESCRIPTION

This is the power source circuit to operate the radio and display receiver assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY POWER SOURCE) |

(a) Disconnect the E4 and E42 radio and display receiver assembly connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E4-7 (GND1) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E4-4 (+B1) - E4-7 (GND1) |

Always |

11 to 14 V |

|

E4-3 (ACC1) - E4-7 (GND1) |

Ignition switch ACC |

11 to 14 V |

|

E42-1 (IG) - E4-7 (GND1) |

Ignition switch ON |

11 to 14 V |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Microphone Circuit between Microphone and Radio Receiver

Microphone Circuit between Microphone and Radio Receiver

DESCRIPTION

The radio and display receiver assembly and inner rear view mirror assembly (amplifier

microphone assembly) are connected to each other using the microphone connection

detection signa ...

Front Door Speaker

Front Door Speaker

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the n ...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

bat ...

Lost Communication with Gateway Module (MS Bus) (U1002)

DESCRIPTION

The main body ECU will store this DTC when no signals can be received

from the ECUs that have been memorized as those that are connected to the

CAN MS bus.

When the main body ECU receives a response signal from the ECUs connecte ...

Dtc Check / Clear

DTC CHECK / CLEAR

HINT:

Use the Techstream to read and clear the DTC of the occupant classification ECU,

otherwise the DTCs cannot be read and cleared.

1. DTC CHECK

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ...

0.1575