Toyota Venza: Power Source Circuit

DESCRIPTION

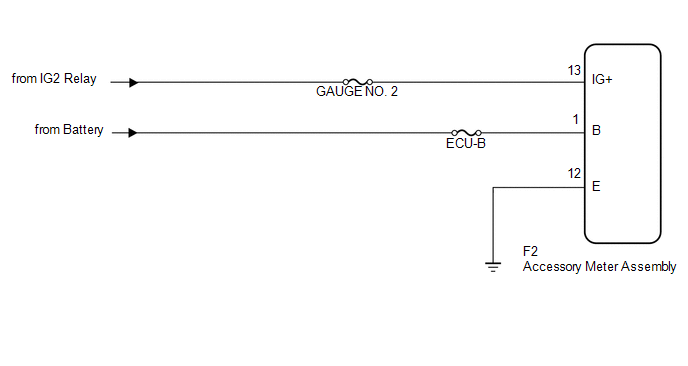

1. w/o Multi-information Display

(a) This circuit is the power source circuit for the accessory meter assembly. This circuit provides two types of power sources; one is a constant power source mainly used as a backup power source, and the other is a power source mainly used for signal transmission.

HINT:

If the accessory meter assembly displays "1:00" when the ignition switch is turned off, then to ON again, the B terminal has a malfunction.

The maximum clock assembly margin of error is -4 to 4 seconds per day when the temperature is between -20°C (-4°F) and 60°C (140°F).

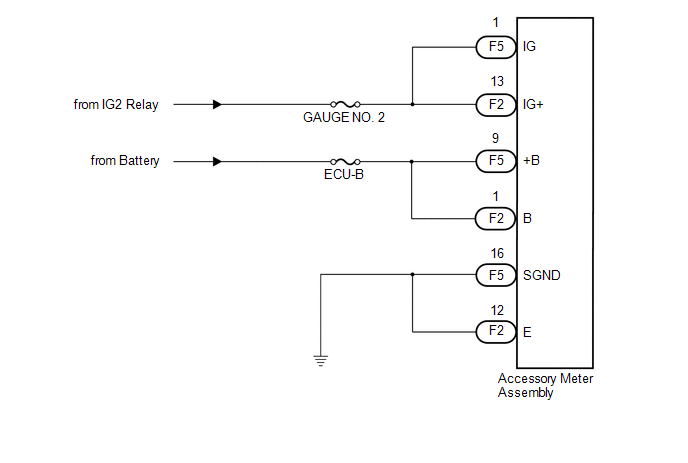

2. w/ Multi-information Display

(a) This circuit is the power source circuit for the accessory meter assembly. This circuit provides two types of power sources; one is a constant power source mainly used as a backup power source, and the other is a power source mainly used for signal transmission.

HINT:

If the accessory meter assembly displays "1:00" when the ignition switch is turned off, then to ON again, the +B terminal has a malfunction.

The maximum clock assembly margin of error is -4 to 4 seconds per day when the temperature is between -20°C (-4°F) and 60°C (140°F).

WIRING DIAGRAM

1. w/o Multi-information Display

2. w/ Multi-information Display

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR |

(a) w/o Multi-information Display

|

(1) Disconnect the F2 connector. |

|

(2) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-1 (B) - Body ground |

Always |

11 to 14 V |

|

F2-13 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

(3) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-12 (E) - Body ground |

Always |

Below 1 Ω |

|

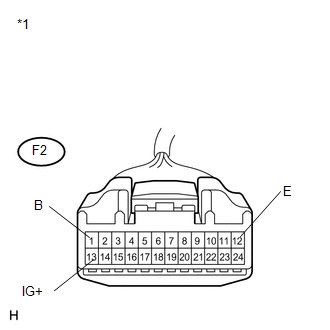

*1 |

Front view of wire harness connector (to Accessory Meter Assembly) |

(b) w/ Multi-information Display

|

(1) Disconnect the F2 and F5 connectors. |

|

(2) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F5-1 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

F5-9 (+B) - Body ground |

Always |

11 to 14 V |

|

F2-1 (B) - Body ground |

Always |

11 to 14 V |

|

F2-13 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

(3) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-12 (E) - Body ground |

Always |

Below 1 Ω |

|

F5-16 (SGND) - Body ground |

Always |

Below 1 Ω |

|

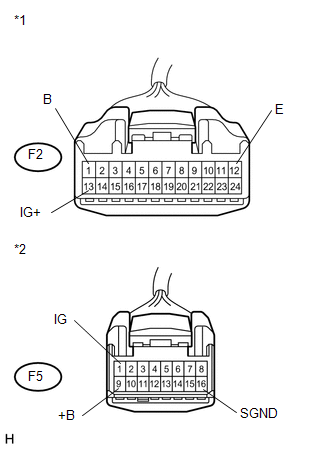

*1 |

Front view of wire harness connector (to Accessory Meter Assembly) |

|

*2 |

Front view of wire harness connector (to Accessory Meter Assembly ) |

| OK | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Speed Signal Circuit

Speed Signal Circuit

DESCRIPTION

The combination meter assembly receives the vehicle speed signal from this circuit.

The wheel speed sensors produce an output that varies according to the vehicle speed.

The wheel spe ...

Mirror (int)

Mirror (int)

...

Other materials about Toyota Venza:

Driver Side Power Mirror cannot be Adjusted with Power Mirror Switch

SYSTEM DESCRIPTION

When the mirror adjust switch is operated, the main body ECU (driver side junction

block assembly) detects the switch operation and sends the mirror adjust switch

signal to the outer mirror control ECU assembly (driver door) via CAN com ...

Dtc Check / Clear

DTC CHECK / CLEAR

1. DTC CHECK/CLEAR (When Using the Techstream)

(a) Check for DTCs.

(1) Connect the Techstream to the DLC3.

(2) Turn the ignition switch to ON.

(3) Turn the Techstream on.

(4) Read the DTCs following the prompts on the Techstream. Enter ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Install the rear wiper motor and bracket assembly with the 3 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(b) C ...

0.1228