Toyota Venza: Power Back Door Control Switch

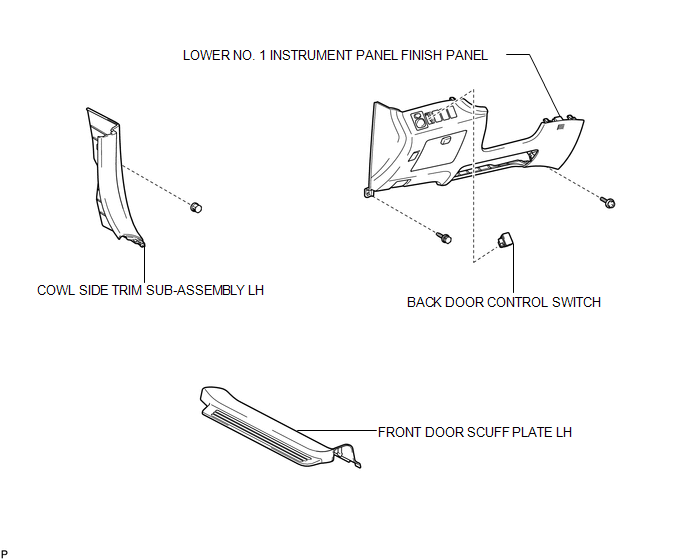

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

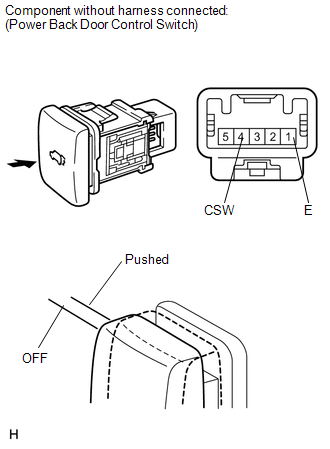

1. INSPECT POWER BACK DOOR OPENER / CLOSER SWITCH

(a) Measure the resistance of the switch.

Standard resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1(E) - 4(CSW) |

Pushed (ON) |

Below 1 Ω |

|

1(E) - 4(CSW) |

Free (OFF) |

10 kΩ or higher |

If the result is not as specified, replace the switch.

(b) Check that the switch illuminates.

Standard resistance:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → 3 (ILL+) Battery negative (-) → 2 (ILL-) |

Illuminates |

If the result is not as specified, replace the switch.

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE LH

.gif)

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

3. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

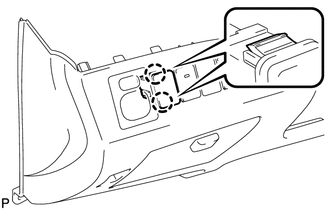

4. REMOVE BACK DOOR CONTROL SWITCH

|

(a) Disengage the 2 claws and remove the back door control switch. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL BACK DOOR CONTROL SWITCH

|

(a) Engage the 2 claws to install the back door control switch. |

|

2. INSTALL LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

3. INSTALL COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

4. INSTALL FRONT DOOR SCUFF PLATE LH

.gif)

Power Back Door Closer Switch

Power Back Door Closer Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE POWER BACK DOOR CLOSER SWITCH ASSEMBLY

(a) Disconnect the con ...

Other materials about Toyota Venza:

Runnable Signal Malfunction (B2286,P0335)

DESCRIPTION

The power management control ECU receives an engine speed signal and information

that indicates whether the engine is running or not. It receives the engine speed

signal from the ECM via a direct line, and the information about whether the eng ...

CD Sound Skips

PROCEDURE

1.

CHECK CD

(a) Check that the CD is not deformed or cracked.

OK:

No deformation or cracks on the CD.

NG

END (CD IS FAULTY)

...

Fuel Tank Cap

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Visually check that the fuel tank cap assembly and gasket are not

deformed or damaged.

Text in Illustration

*a

Gasket

...

0.1266

.png)