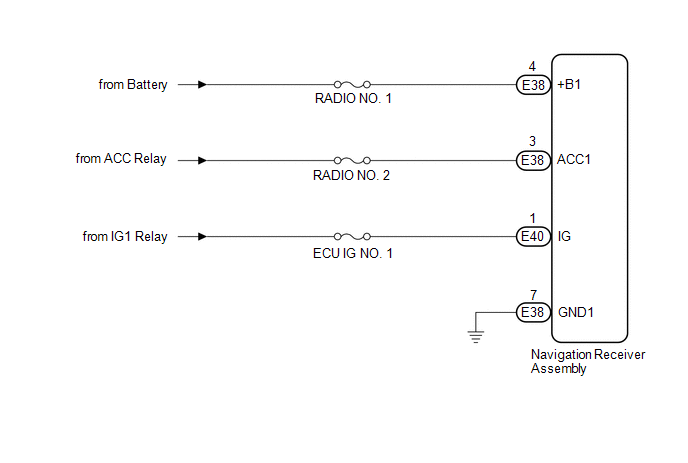

Toyota Venza: Navigation Receiver Assembly Power Source Circuit

DESCRIPTION

This is the power source circuit to operate the navigation receiver assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (NAVIGATION RECEIVER ASSEMBLY POWER SOURCE) |

(a) Disconnect the E38 and E40 navigation receiver assembly connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E38-7 (GND1) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E38-4 (+B1) - E38-7 (GND1) |

Always |

11 to 14 V |

|

E38-3 (ACC1) - E38-7 (GND1) |

Ignition switch ACC |

11 to 14 V |

|

E40-1 (IG) - E38-7 (GND1) |

Ignition switch ON |

11 to 14 V |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Microphone Circuit between Microphone and Navigation Receiver Assembly

Microphone Circuit between Microphone and Navigation Receiver Assembly

DESCRIPTION

The navigation receiver assembly and inner rear view mirror assembly

(amplifier microphone assembly) are connected to each other using the microphone

connection detection s ...

Other materials about Toyota Venza:

Weight limits

• The gross trailer weight must never exceed TWR described in the table. • The

gross combination weight must never exceed the GCWR described in the table.

• The gross vehicle weight must never exceed the GVWR indicated on the Certification

Label. ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT SPEEDOMETER

(a) Check the operation.

(1) Using a speedometer tester (calibrated chassis dynamometer), check the speedometer

indication according to the table below.

Reference:

Chassis Dynamometer In ...

Combination Meter

Components

COMPONENTS

ILLUSTRATION

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE COMBINATION METER GLASS

(a) Disengage the 9 claws to remove the combination meter glass.

Removal

REMOVAL

...

0.1306