Toyota Venza: Luggage Compartment Room Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

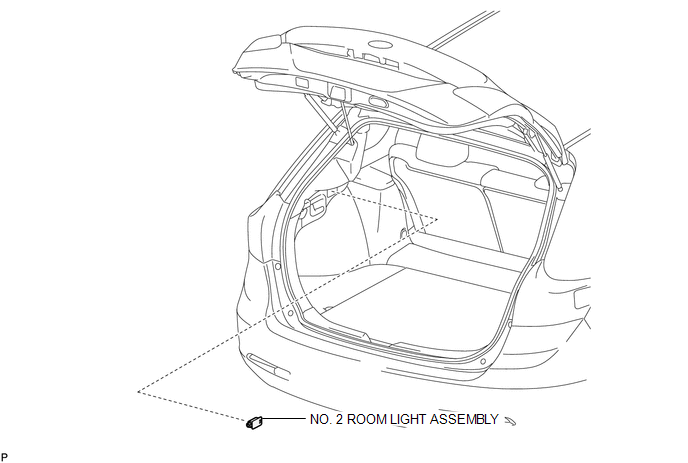

1. REMOVE NO. 2 ROOM LIGHT ASSEMBLY

|

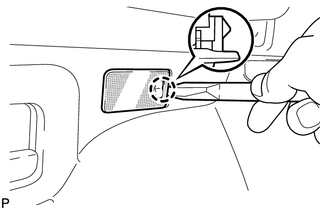

(a) Using a moulding remover, disengage the claw. |

|

(b) Disconnect the connector and remove the No. 2 room light assembly.

Inspection

INSPECTION

PROCEDURE

1. INSPECT NO. 2 ROOM LIGHT ASSEMBLY

|

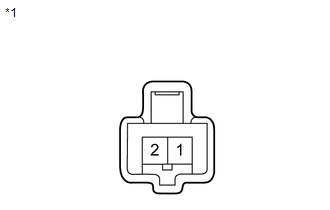

(a) Connect a positive (+) lead from the battery to terminal 1 and a negative (-) lead to terminal 2. |

|

(b) Check that the light comes on.

OK:

Light comes on.

Text in Illustration|

*1 |

Component without harness connected (No. 2 Room Light Assembly) |

If the result is not as specified, replace the bulb or No. 2 room light assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 2 ROOM LIGHT ASSEMBLY

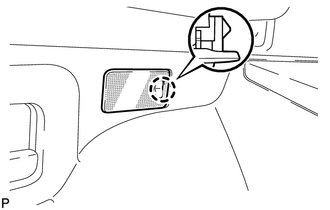

(a) Connect the connector.

|

(b) Engage the claw to install the No. 2 room light assembly. |

|

Door Unlock Detection Switch Circuit

Door Unlock Detection Switch Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) detects the condition

of the door unlock detection switch.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USI ...

Personal Light

Personal Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE MAP LIGHT ASSEMBLY

(a) Using a moulding remover, disengage the 2 claws and 2 clips.

Text in Illustrati ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT OUTER MIRROR SWITCH ASSEMBLY (w/o Memory)

(a) The L position of the left/right adjustment switch: Measure the resistance

according to the value(s) in the table below.

Standard Resistance (for Left Side):

Tes ...

Clearance Sonar Main Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE LH

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

3. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

4. REMOVE CLEARANCE SONAR MAIN SWITCH

...

Vehicle Speed Signal Malfunction (B2282)

DESCRIPTION

The power management control ECU receives vehicle speed information using 2 methods.

It receives a speed signal from the meter ECU. It also receives speed information

from the meter ECU via CAN. If the information sent using these 2 methods is ...

0.1157