Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

|

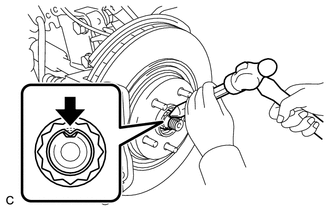

(a) Align the splines of the shaft and install the drive shaft assembly LH using a brass bar and a hammer. NOTICE:

|

|

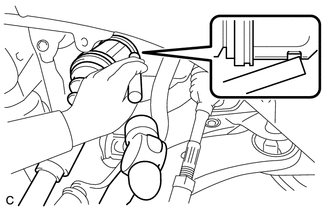

(b) Apply a total of 0.1 to 0.3g (0.00353 to 0.0105 oz.) of Toyota Body Grease W to the 8 areas shown in the illustration.

.png) Text in Illustration

Text in Illustration

.png) |

Toyota Body Grease W |

NOTICE:

Do not apply grease to the serrations or installation hole of the front speed sensor.

2. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for 2WD)

(a) Install the front drive shaft assembly RH.

|

(b) Install the bearing bracket hole snap ring and a new bolt. Torque: 32 N·m {330 kgf·cm, 24 ft·lbf} NOTICE:

|

|

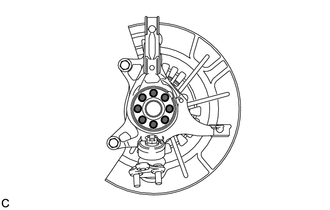

(c) Apply a total of 0.1 to 0.3g (0.00353 to 0.0105 oz.) of Toyota Body Grease W to the 8 areas shown in the illustration.

Text in Illustration

Text in Illustration

.png) |

Toyota Body Grease W |

NOTICE:

Do not apply grease to the serrations or installation hole of the front speed sensor.

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for AWD)

(a) Install the front drive shaft assembly RH.

|

(b) Install the bearing bracket hole snap ring and a new bolt. Torque: 32 N·m {330 kgf·cm, 24 ft·lbf} NOTICE:

|

|

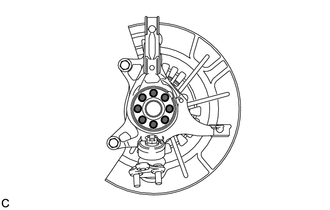

(c) Apply a total of 0.1 to 0.3g (0.00353 to 0.0105 oz.) of Toyota Body Grease W to the 8 areas shown in the illustration.

Text in Illustration

Text in Illustration

.png) |

Toyota Body Grease W |

NOTICE:

Do not apply grease to the serrations or installation hole of the front speed sensor.

4. INSTALL FRONT AXLE ASSEMBLY

.gif)

5. INSTALL FRONT LOWER SUSPENSION ARM

.gif)

6. CONNECT TIE ROD ASSEMBLY

.gif)

7. INSTALL FRONT SPEED SENSOR

|

(a) Install the front speed sensor and front flexible hose with the bolt. Torque: 19 N·m {194 kgf·cm, 14 ft·lbf} NOTICE:

|

|

|

(b) Install the front speed sensor to the steering knuckle with the bolt. Torque: 8.5 N·m {87 kgf·cm, 75 in·lbf} NOTICE:

|

|

8. INSTALL FRONT STABILIZER LINK ASSEMBLY

.gif)

9. INSTALL FRONT AXLE SHAFT NUT

(a) Clean the threaded parts on the front drive shaft and a new front axle shaft nut using a non-residue solvent.

HINT:

- Be sure to perform this work for a new drive shaft.

- Keep the threaded parts free of oil and foreign matter.

|

(b) Install the new front axle shaft nut. Torque: 294 N·m {2998 kgf·cm, 217 ft·lbf} |

|

(c) Using a chisel and hammer, stake the front axle shaft nut.

10. INSTALL FRONT WHEELS

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

11. ADD TRANSFER OIL (for AWD)

12. ADJUST TRANSFER OIL (for AWD)

.gif)

13. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

- for U660E: See page

.gif)

- for U660F: See page

.gif)

- for U760E: See page

.gif)

- for U760F: See page

.gif)

14. ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page .gif) )

)

15. CHECK ABS SPEED SENSOR SIGNAL

HINT:

(See page .gif) )

)

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL BEARING BRACKET HOLE SNAP RING (for RH Side)

(a) Install a new bearing bracket hole snap ring to the front drive shaft assembly

RH.

2. INSTALL FRONT DRIVE SHAFT B ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

(a) Install a new gasket to the sensor.

Text in Illustration

*1

New Gasket

...

Data Signal Circuit between Navigation Receiver Assembly and Stereo Jack Adapter

DESCRIPTION

The No. 1 stereo jack adapter assembly sends the sound data signal or image data

signal from a USB device to the navigation receiver assembly via this circuit.

WIRING DIAGRAM

PROCEDURE

1.

CHECK HARNESS AND CONNECTOR ( ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

NOTICE:

When install a new brake master cylinder sub-assembly, remove the protectors

from the piston and outlet ports.

(a) Install a new O-ring to the brake master cylinder sub-assembl ...

0.1162

.png)

.png)

.png)

.png)