Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN REAR DISC BRAKE BLEEDER PLUG

(a) Temporarily tighten the rear disc brake bleeder plug.

HINT:

Fully tighten the rear disc brake bleeder plug after bleeding any air left in the system.

(b) Install the rear disc brake bleeder plug cap.

2. INSTALL REAR DISC

|

(a) Align the matchmarks of the rear disc and axle hub, and install the rear disc. Text in Illustration

NOTICE: When installing a new rear disc, select the installation position where the rear disc has minimal runout. |

|

3. INSTALL PARKING BRAKE SHOE ADJUSTING HOLE PLUG

4. INSTALL REAR DISC BRAKE CYLINDER MOUNTING

|

(a) Install the rear disc brake cylinder mounting with the 2 bolts. Torque: 78 N·m {800 kgf·cm, 58 ft·lbf} |

|

5. INSTALL REAR DISC BRAKE BUSHING DUST BOOT

|

(a) Apply a light layer of lithium soap base glycol grease to the seal surfaces of 2 new rear disc brake bushing dust boots. HINT: Apply at least 0.3 g (0.01 oz.) of lithium soap base glycol grease to each rear disc brake bushing dust boot. |

|

|

(b) Install the 2 rear disc brake bushing dust boots to the rear disc brake cylinder mounting. |

|

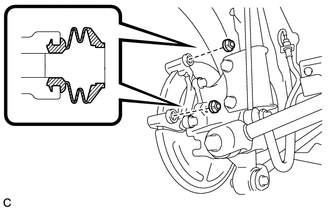

6. INSTALL NO. 2 REAR DISC BRAKE CYLINDER SLIDE PIN

|

(a) Apply a light layer of lithium soap base glycol grease to the sliding part and the seal surface of the No. 2 rear disc brake cylinder slide pin. |

|

|

(b) Install the No. 2 rear disc brake cylinder slide pin to the rear disc brake cylinder mounting. |

|

(c) Push the No. 2 rear disc brake cylinder slide pin into the rear disc brake bushing dust boot to align them.

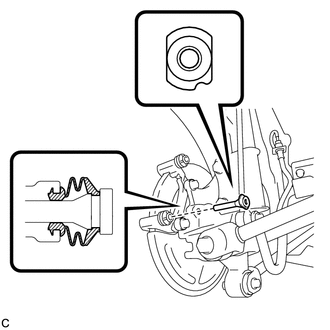

7. INSTALL REAR DISC BRAKE CYLINDER SLIDE BUSHING

|

(a) Apply a light layer of lithium soap base glycol grease to the contact surface of the No. 1 rear disc brake cylinder slide pin. |

|

(b) Install a new rear disc brake cylinder slide bushing to the No. 1 rear disc brake cylinder slide pin.

8. INSTALL NO. 1 REAR DISC BRAKE CYLINDER SLIDE PIN

|

(a) Apply a light layer of lithium soap base glycol grease to the sliding part and the seal surface of the No. 1 rear disc brake cylinder slide pin. |

|

|

(b) Install the No. 1 rear disc brake cylinder slide pin to the rear disc brake cylinder mounting. |

|

(c) Push the No. 1 rear disc brake cylinder slide pin into the rear disc brake bushing dust boot to align them.

9. INSTALL REAR DISC BRAKE PAD SUPPORT PLATE

|

(a) Install the 2 rear disc brake pad support plates to the rear disc brake cylinder mounting. NOTICE: Be sure to install the plates in the correct position and direction. |

|

10. INSTALL REAR ANTI-SQUEAL SHIM

(a) Install the rear anti-squeal shims to the 2 rear brake pads.

NOTICE:

- When replacing worn pads, the rear anti-squeal shims must be replaced together with the pads.

- Install the shims in the correct positions and directions.

11. INSTALL REAR DISC BRAKE PAD

|

(a) Install the 2 rear disc brake pads to the rear disc brake cylinder mounting. NOTICE:

|

|

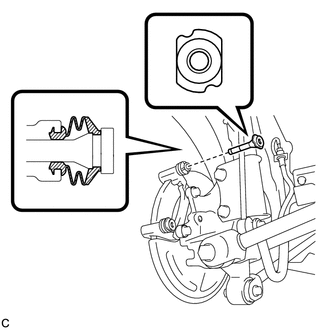

12. INSTALL REAR DISC BRAKE CYLINDER ASSEMBLY

|

(a) Install the rear disc brake cylinder assembly to the rear disc brake cylinder mounting with the 2 bolts. Torque: 32 N·m {326 kgf·cm, 24 ft·lbf} |

|

13. CONNECT REAR FLEXIBLE HOSE

|

(a) Connect the rear flexible hose to the rear disc brake cylinder assembly with a new union bolt and a new gasket. Torque: 29 N·m {300 kgf·cm, 22 ft·lbf} HINT: Install the rear flexible hose lock securely into the lock hole in the rear disc brake cylinder assembly. |

|

14. FILL RESERVOIR WITH BRAKE FLUID

.gif)

15. BLEED BRAKE LINE

.gif)

16. INSPECT FOR BRAKE FLUID LEAK

17. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

18. ADJUST PARKING BRAKE

.gif)

19. INSTALL REAR WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT PAD LINING THICKNESS

(a) Using a ruler, measure the pad lining thickness.

Text in Illustration

*1

Ruler

...

Rear Brake Flexible Hose

Rear Brake Flexible Hose

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

If both the left and right side hoses are removed at the same time, be sure to

place identification ma ...

Other materials about Toyota Venza:

Transmission Control Switch Circuit

DESCRIPTION

When the shift lever is in S and it is moved toward "-" or "+", it is possible

to select different shift ranges (1st through 6th ranges).

Moving the shift lever toward "+" increases the shift range by one, and movi ...

Precaution

PRECAUTION

1. BEFORE WORKING ON FUEL SYSTEM

(a) When disconnecting a fuel line, fuel will splash. So observe the following

precautions:

(1) Do not smoke or work near fire when handling the fuel system.

(2) Keep gasoline away from rubber or leather parts. ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the cruise control system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

0.1233

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)