Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL LEVEL

|

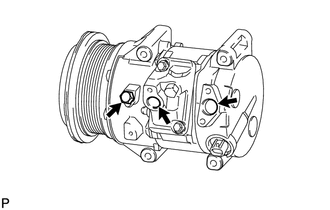

(a) When replacing the cooler compressor assembly with a new one, gradually discharge the inert gas (helium) from the service valve, and drain the following amount of oil from the vents indicated by the arrows in the illustration before installation. HINT: The drain bolt and washer can be reused. Standard: (Oil capacity inside the new compressor assembly with pulley: 130 + 15 cc (4.4 + 0.51 fl.oz.) ) - (Remaining oil amount in the removed compressor assembly with pulley) = (Oil amount to be removed from the new compressor when replacing) NOTICE:

|

|

2. INSTALL COMPRESSOR ASSEMBLY WITH PULLEY

|

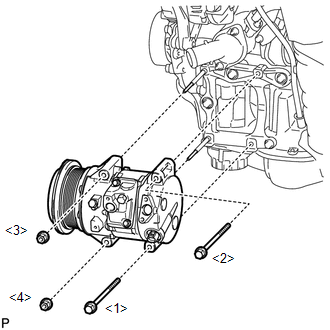

(a) Using an E8 "TORX" socket wrench, install the 2 stud bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

|

(b) Install the the 2 bolts and 2 nuts to the compressor assembly with pulley. Torque: 25 N·m {255 kgf·cm, 18 ft·lbf} NOTICE: Tighten the bolts and nuts in the order shown in the illustration to install the compressor assembly with pulley. |

|

3. CONNECT SUCTION HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the hose.

(b) Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor assembly with pulley.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring onto the suction hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surfaces free from dirt or any foreign objects.

|

(d) Install the suction hose sub-assembly onto the compressor assembly with pulley with the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

4. CONNECT COOLER REFRIGERANT DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor assembly with pulley.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring onto the discharge hose.

NOTICE:

Keep the O-ring and O-ring fitting surfaces free from dirt or any foreign objects.

|

(d) Install the cooler refrigerant discharge hose onto the compressor assembly with pulley with the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

|

(e) Using pliers, grip the claws of the clip and slide the clip to install the No. 2 radiator hose. |

|

|

(f) Engage each clamp. |

|

(g) Connect each connector.

5. INSTALL RADIATOR ASSEMBLY

HINT:

Refer to the procedure for Install Radiator Assembly (See page

.gif) ).

).

6. INSTALL V-RIBBED BELT

.gif)

7. INSTALL FRONT FENDER APRON SEAL RH

.gif)

8. INSTALL FRONT FENDER LINER RH

9. INSTALL FRONT WHEEL RH

.gif)

10. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

11. CHARGE WITH REFRIGERANT

.gif)

12. WARM UP ENGINE

.gif)

13. INSPECT FOR REFRIGERANT LEAK

.gif)

14. INSTALL NO. 1 ENGINE UNDER COVER

Removal

Removal

REMOVAL

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized ...

Other materials about Toyota Venza:

Door Courtesy Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE COURTESY LIGHT ASSEMBLY

(a) Using a screwdriver wrapped with protective tape, disengage the claw.

Text in Illustration

*1

Pro ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Be sure to follow the correct removal and installation procedures of the driver

side knee airbag assembly.

PROCEDURE

1. INSPECT DRIVER SIDE KNEE AIRBAG ASSEMBLY (VEHICLE NOT INVOLVED IN COLLISION)

...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE RADIATOR ASSEMBLY

HINT:

See page

3. REMOVE V-RIBBE ...

0.1325

.png)

.png)

.png)

.png)

.png)