Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 MANIFOLD CONVERTER INSULATOR

|

(a) Install the No. 1 manifold converter insulator to the exhaust manifold converter sub-assembly with the 4 bolts. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

2. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

|

(a) Install the No. 2 exhaust manifold heat insulator to the exhaust manifold converter sub-assembly with the 2 bolts. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

3. INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

|

(a) Install a new gasket onto the cylinder head sub-assembly. |

|

|

(b) Temporarily install the exhaust manifold converter sub-assembly to the cylinder head sub-assembly with the 5 nuts. |

|

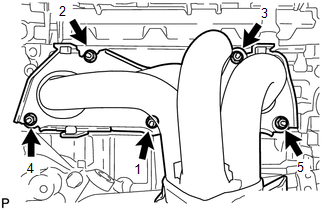

(c) Tighten the 5 nuts in the order shown in the illustration.

Torque:

35 N·m {357 kgf·cm, 26 ft·lbf}

4. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

|

(a) Install the No. 1 exhaust manifold heat insulator to the exhaust manifold converter sub-assembly with the 4 bolts. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

5. INSTALL NO. 2 MANIFOLD STAY

|

(a) Install the No. 2 manifold stay to the exhaust manifold converter sub-assembly and stiffening crankcase assembly with the bolt and nut. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

6. INSTALL MANIFOLD STAY

|

(a) Install the manifold stay to the exhaust manifold converter sub-assembly and stiffening crankcase assembly with the bolt and nut. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

7. INSTALL AIR FUEL RATIO SENSOR

.gif)

8. INSTALL FRONT EXHAUST PIPE ASSEMBLY

|

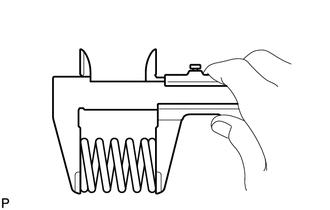

(a) Using a vernier caliper, measure the free length of the compression spring. Minimum Free Length: 41.5 mm (1.63 in.) If the length is less than the minimum, replace the compression spring. |

|

(b) Temporarily install a new gasket to the exhaust manifold converter sub-assembly.

|

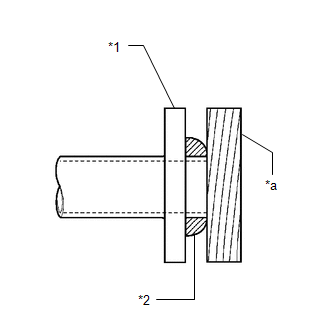

(c) Using a plastic hammer and wooden block, tap in the gasket until its surface is flush with the exhaust manifold converter sub-assembly. Text in Illustration

NOTICE:

|

|

(d) Install a new gasket to the center exhaust pipe assembly.

|

(e) Install the front exhaust pipe assembly to the exhaust manifold converter sub-assembly and center exhaust pipe assembly with the 2 compression springs and 4 bolts. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

|

(f) Connect the heated oxygen sensor connector. |

|

9. INSPECT FOR EXHAUST GAS LEAK

.gif)

10. INSTALL NO. 2 ENGINE UNDER COVER

11. INSTALL NO. 1 ENGINE UNDER COVER

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Wear protective gloves when removing the exhaust pipe.

The exhaust pipe is extremely hot immediately after the engine has stopped.

...

Exhaust Pipe

Exhaust Pipe

...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT SEAT FRAME WITH ADJUSTER LH

(a) Check operation of the seat frame (slide motor).

(1) w/ Memory:

Check if the seat frame moves smoothly when the battery is connected

to the slide motor connector termin ...

XM Tuner Malfunction (B15BA)

DESCRIPTION

This DTC is stored when a malfunction occurs in the stereo component tuner assembly.

DTC No.

DTC Detection Condition

Trouble Area

B15BA

When either of the following conditions is met:

...

Vehicle Speed Sensor "A" (P0500)

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU.

The skid control ECU converts these wheel speed signals into a 4-pulse signal

and outputs it to the ECM via the combination meter. The ECM det ...

0.1155

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)