Toyota Venza: Inspection

INSPECTION

PROCEDURE

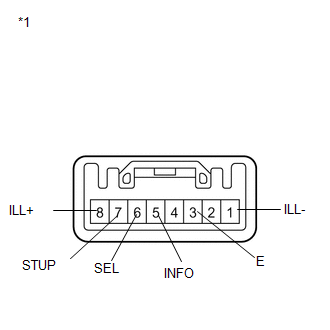

1. INSPECT DRIVE MONITOR SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (E) - 5 (INFO) |

INFO CLOCK*1 or INFO*2 switch is pressed |

Below 1 Ω |

|

3 (E) - 5 (INFO) |

INFO CLOCK*1 or INFO*2 switch is released |

10 kΩ or higher |

|

3 (E) - 6 (SEL) |

RESET H *1 or SELECT RESET*2 switch is pressed |

Below 1 Ω |

|

3 (E) - 6 (SEL) |

RESET H *1 or SELECT RESET*2 switch is released |

10 kΩ or higher |

|

3 (E) - 7 (STUP) |

US/M M*1 or SETUP*2 switch is pressed |

Below 1 Ω |

|

3 (E) - 7 (STUP) |

US/M M*1 or SETUP*2 switch is released |

10 kΩ or higher |

- *1: w/o Rear View Monitor System

- *2: w/ Rear View Monitor System

(b) Apply battery voltage from the wire harness back side between the terminals of the switch, and check the lighting condition of the drive monitor switch.

OK:

|

Measurement Condition |

Condition |

Specified Condition |

|---|---|---|

|

Battery negative (-) → 1 (ILL-) Battery positive (+) → 8 (ILL+) |

Always |

Drive monitor switch illuminates |

|

*1 |

Component without harness connected (Drive Monitor Switch) |

HINT:

If the result is not as specified, replace the drive monitor switch (See page

.gif) ).

).

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

...

Other materials about Toyota Venza:

Accessory Meter

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL ACCESSORY METER ASSEMBLY (w/o Rear View Monitor System)

(a) Connect the connector.

(b) Engage the 2 clamps ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR BUMPER UPPER RETAINER

(a) Engage the guide.

(b) Install the rear bumper upper retainer with the 2 screws.

2. INSTALL REAR TURN SIGNAL LIGHT BULB

(a) Install th ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT SEAT HEADREST ASSEMBLY

2. REMOVE FRONT SEAT REAR OUTER TRACK COVER

3. REMOVE FRONT SEAT REAR INNER TRACK COVER

4. REMOVE FRONT SEAT ASSEMBLY

5. REMOVE RECLINING POWER SEAT SWITCH KNOB

6. REMOVE SLIDE AND VER ...

0.1368