Toyota Venza: Accessory Meter

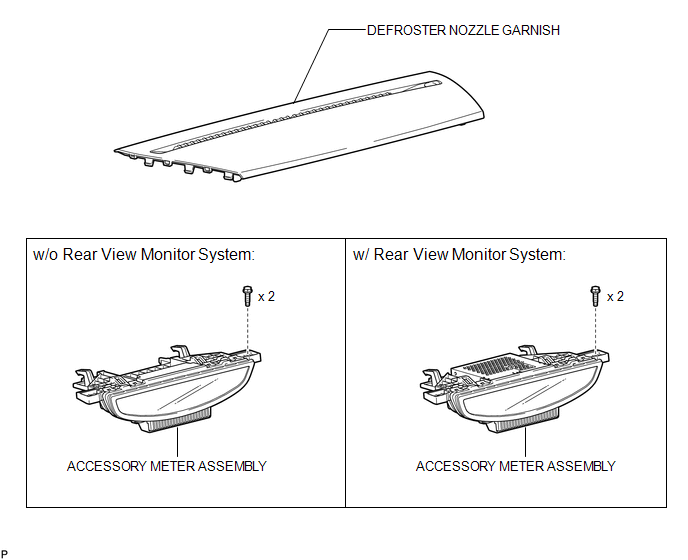

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL ACCESSORY METER ASSEMBLY (w/o Rear View Monitor System)

|

(a) Connect the connector. |

|

(b) Engage the 2 clamps.

|

(c) Engage the 2 clips. |

|

(d) Install the accessory meter assembly with the 2 bolts.

2. INSTALL ACCESSORY METER ASSEMBLY (w/ Rear View Monitor System)

|

(a) Connect the connectors. |

|

(b) Engage the 2 clamps.

|

(c) Engage the 2 clips. |

|

(d) Install the accessory meter assembly with the 2 bolts.

3. INSTALL DEFROSTER NOZZLE GARNISH

.gif)

Removal

REMOVAL

PROCEDURE

1. REMOVE DEFROSTER NOZZLE GARNISH

.gif)

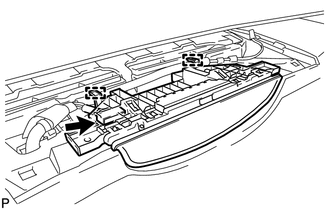

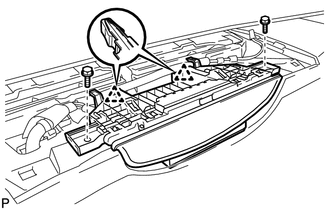

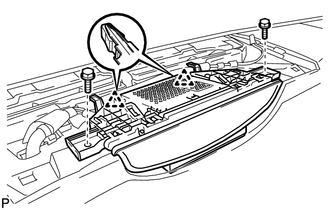

2. REMOVE ACCESSORY METER ASSEMBLY (w/o Rear View Monitor System)

|

(a) Remove the 2 bolts. |

|

(b) Disengage the 2 clips.

|

(c) Disengage the 2 clamps. |

|

(d) Disconnect the connector and remove the accessory meter assembly.

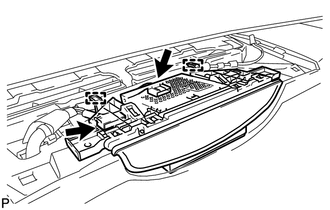

3. REMOVE ACCESSORY METER ASSEMBLY (w/ Rear View Monitor System)

|

(a) Remove the 2 bolts. |

|

(b) Disengage the 2 clips.

|

(c) Disengage the 2 clamps. |

|

(d) Disconnect the connectors and remove the accessory meter assembly.

Clock System

Clock System

...

Other materials about Toyota Venza:

Operation Check

OPERATION CHECK

1. CHECK NAVIGATION SYSTEM NORMAL CONDITION

(a) If the symptom is applicable to any of the following, it is intended behavior,

and not a malfunction.

Symptom

Answer

A longer route than expected is cho ...

Tire Pressure Warning Receiver

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE RO ...

Center Airbag Sensor Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Center Airbag Sensor Communication Stop Mode

"SRS Airbag" is not displayed on "CAN Bus Check" screen of the

Techs ...

0.1532

.png)

.png)

.png)

.png)