Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT PRELOAD

|

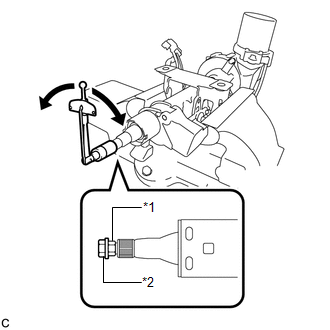

(a) Secure the steering column assembly in a vise. Text in Illustration

NOTICE: When using a vise, do not overtighten it. |

|

(b) Install a service nut to the steering main shaft.

Recommended service nut:

Thread diameter

12.0 mm (0.472 in.)

Thread pitch

1.25 mm (0.0492 in.)

(c) Install the steering wheel assembly set nut to the steering main shaft.

(d) Lock the steering wheel assembly set nut using the service nut.

(e) Using a torque wrench, turn the main shaft and measure the preload.

Torque:

Preload :

0.98-1.58 N·m {10-16 kgf·cm, 9-13 in·lbf}

If the preload is not as specified, replace the steering column assembly.

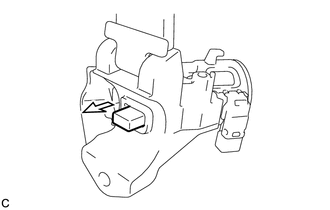

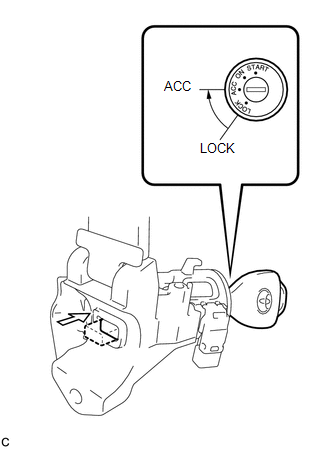

2. INSPECT STEERING LOCK OPERATION (w/o Smart Key System)

|

(a) Check that the steering lock mechanism is activated when the key is removed. |

|

|

(b) Check that the steering lock mechanism is deactivated when the key is inserted and turned to the ACC position. HINT: If there is any abnormality, replace the ignition switch lock cylinder assembly or steering column upper bracket assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When using a vise, do not overtighten it.

PROCEDURE

1. REMOVE STEERING LOCK ACTUATOR ASSEMBLY (w/ Smart Key System)

(a) Secure the steering column ass ...

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When using a vise, do not overtighten it.

PROCEDURE

1. INSTALL STEERING LOCK ACTUATOR ASSEMBLY (w/ Smart Key System)

(a) Secure the steering column ass ...

Other materials about Toyota Venza:

Throttle / Pedal Position Sensor "A" Minimum Stop Performance (P2109)

DESCRIPTION

The idle speed is controlled by the Electronic Throttle Control System (ETCS).

The ETCS is comprised of a throttle actuator, which operates the throttle valve,

and a throttle position sensor, which detects the opening amount of the throttle

...

System Diagram

SYSTEM DIAGRAM

1. MIRROR CONTROL SYSTEM

Communication Table

Sender

Receiver

Signal / Signal Condition

Line

Main body ECU (driver side junction block assembly)

Outer mirror control EC ...

Power Source Mode does not Change to ON (IG and ACC)

DESCRIPTION

When the engine switch is pushed with the electrical key in the cabin, the power

management control ECU receives signals to change the power source mode.

HINT:

To allow use of the Techstream to inspect the push-button start function when

the ...

0.1506