Toyota Venza: Ignition Hold Monitor Malfunction (B2271)

DESCRIPTION

This DTC is stored when a problem such as an open in the AM2 fuse, an open or short in the wire harness between the fuse and power management control ECU, a short in the IG output circuit inside the power management control ECU, a short between the power management control ECU and relay, or a short in the relay is detected.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2271 |

The hold circuit, IG1 relay actuation circuit or IG2 relay actuation circuit inside the power management control ECU is open or shorted. |

|

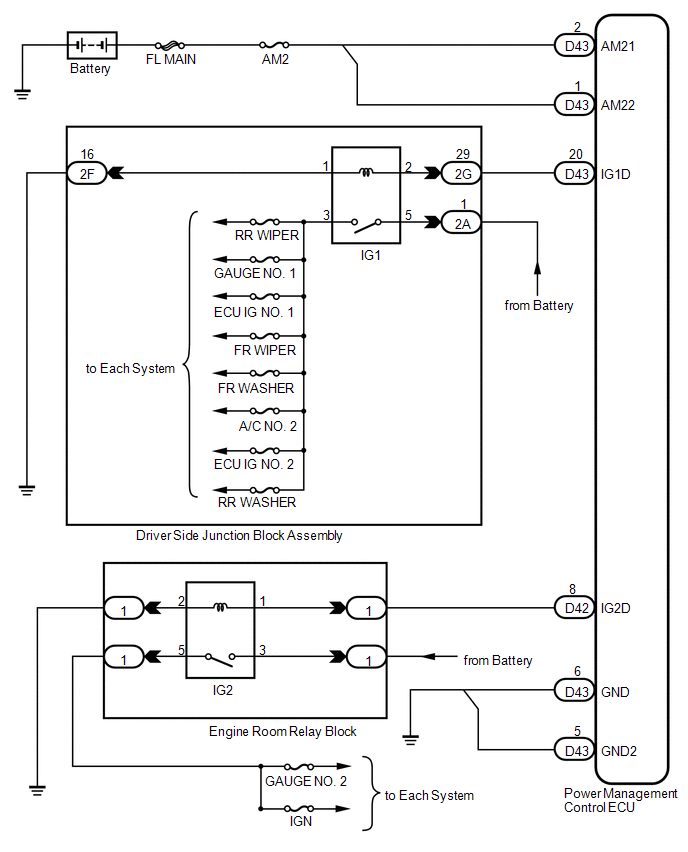

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When the power management control ECU is replaced with a new one and the cable from the negative (-) battery terminal is connected, the power source mode becomes the on (IG) mode. When the battery is removed and reinstalled, the power source mode that was selected when the battery was removed is restored.

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

|

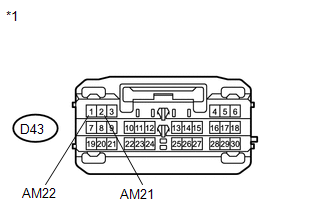

(a) Disconnect the D43 connector from the power management control ECU. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D43-1 (AM22) - Body ground |

Always |

9.5 to 16 V |

|

D43-2 (AM21) - Body ground |

Always |

9.5 to 16 V |

|

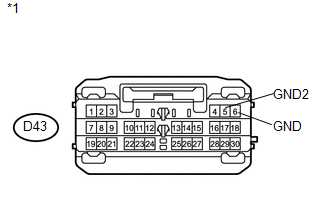

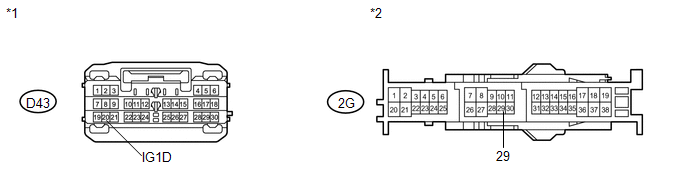

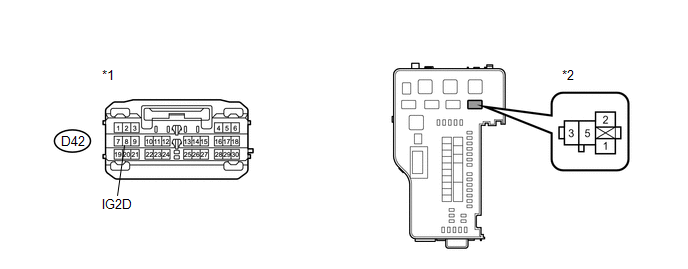

*1 |

Front view of wire harness connector (to Power Management Control ECU) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

|

(a) Disconnect the D43 connector from the power management control ECU. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D43-5 (GND2) - Body ground |

Always |

Below 1 Ω |

|

D43-6 (GND) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Power Management Control ECU) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - DRIVER SIDE JUNCTION BLOCK) |

(a) Disconnect the 2G connector from the main body ECU (driver side junction block assembly).

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D43-20 (IG1D) - 2G-29 |

Always |

Below 1 Ω |

|

D43-20 (IG1D) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Management Control ECU) |

*2 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - DRIVER SIDE JUNCTION BLOCK) |

|

|

4. |

CHECK HARNESS AND CONNECTOR |

|

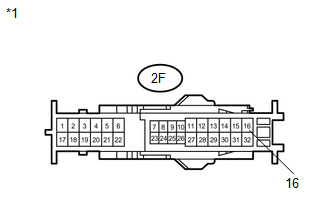

(a) Disconnect the 2F connector from the main body ECU (driver side junction block assembly). |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2F-16 - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

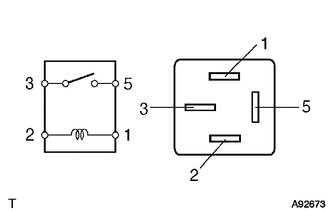

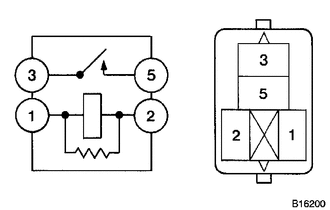

INSPECT IG1 RELAY |

|

(a) Remove the IG1 relay from the main body ECU (driver side junction block assembly). |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

Always |

93.8 to 136.4 Ω |

|

3 - 5 |

When battery voltage is not applied to terminals 1 and 2 |

10 kΩ or higher |

|

3 - 5 |

When battery voltage is applied to terminals 1 and 2 |

Below 1 Ω |

| NG | .gif) |

REPLACE IG1 RELAY |

|

|

6. |

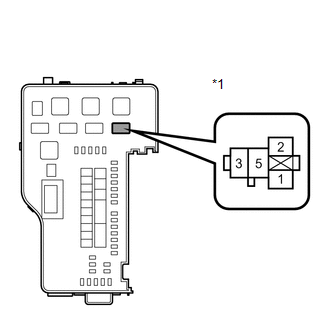

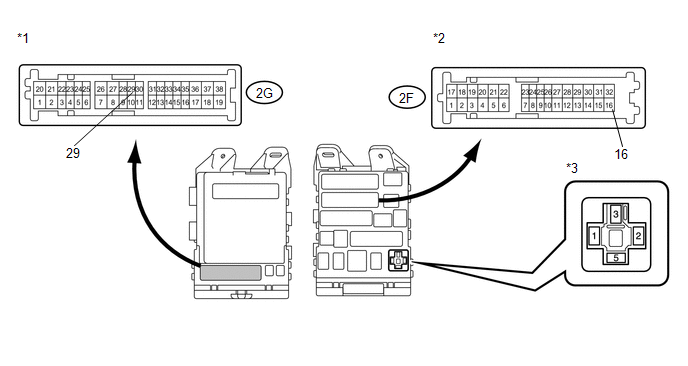

INSPECT MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

(a) Remove the main body ECU (driver side junction block assembly).

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2G-29 - IG1 relay terminal 2 |

Always |

Below 1 Ω |

|

2G-29 - Body ground |

Always |

10 kΩ or higher |

|

2F-16 - IG1 relay terminal 1 |

Always |

Below 1 Ω |

|

2F-16 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Components without harness connected (Main Body ECU (Driver Side Junction Block Assembly)) |

*3 |

Component without relay connected (IG1 relay terminal) |

|

*2 |

Components without harness connected (Main Body ECU (Driver Side Junction Block Assembly)) |

- |

- |

| NG | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

|

|

7. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - IG2 RELAY) |

(a) Disconnect the D42 connector from the power management control ECU.

(b) Remove the IG2 relay from the engine room relay block.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D42-8 (IG2D) - IG2 relay terminal 1 |

Always |

Below 1 Ω |

|

D42-8 (IG2D) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connected (to Power Management Control ECU) |

*2 |

Component without relay connected (IG2 relay terminal) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - IG2 RELAY) |

|

|

8. |

CHECK HARNESS AND CONNECTOR (IG2 RELAY - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (IG2 RELAY - BODY GROUND) |

|

|

9. |

INSPECT IG2 RELAY |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

REPLACE IG2 RELAY |

Vehicle Speed Sensor Malfunction (B2283)

Vehicle Speed Sensor Malfunction (B2283)

DESCRIPTION

The skid control ECU converts wheel speed sensor signals into 4-pulse signals

and sends them to the combination meter. After this signal is converted into a more

precise rectangular w ...

Brake Signal Malfunction (B2284)

Brake Signal Malfunction (B2284)

DESCRIPTION

The power management control ECU receives brake signal information from 2 sources.

It receives a signal from the stop light switch assembly via a direct line, and

a signal from the EC ...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPARATE REAR FLEXIBLE HOSE

3. SEPARATE REAR DI ...

Only Wireless Control Function is Inoperative

DESCRIPTION

The door control receiver receives signals from the transmitter and sends these

signals to the main body ECU. The main body ECU then controls all doors by sending

lock/unlock signals to each door, and sends hazard flasher relay signals to the ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

NOTICE:

Turn the ignition switch off before removing any parts.

HINT:

If no malfunction is found when inspecting parts, inspect the skid control

ECU and ground points for poor connections.

If a trouble code is ...

0.1279

.gif)