Toyota Venza: Engine

General Maintenance

GENERAL MAINTENANCE

CAUTION / NOTICE / HINT

HINT:

Perform these procedures after the engine has cooled down.

PROCEDURE

1. INSPECT DRIVE BELT

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

2. REPLACE ENGINE OIL AND OIL FILTER

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

3. REPLACE ENGINE COOLANT

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

4. INSPECT SPARK PLUGS

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

5. INSPECT BATTERY

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

6. INSPECT AIR CLEANER FILTER ELEMENT

(a) Remove the air filter.

|

(b) Check that the air cleaner is not excessively dirty. If the air cleaner is excessively dirty, replace the air cleaner filter element. |

|

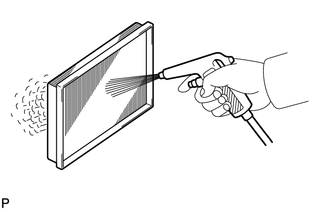

(c) If cleaning the air cleaner filter element, blow compressed air as shown in the illustration to clean it.

(d) Reinstall the air filter.

7. INSPECT EXHAUST PIPES AND MOUNTINGS

(a) Visually check the pipes, hangers and connections for severe corrosion, leaks or damage.

8. INSPECT FUEL TANK CAP GASKET

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

9. INSPECT FUEL LINES, CONNECTIONS, FUEL TANK VAPOR VENT SYSTEM HOSES AND FUEL TANK BANDS

(a) Visually check the fuel lines and hoses for cracks, leaks, loose connections or deformation.

(b) Check for tank band looseness or deformation.

10. INSPECT CHARCOAL CANISTER

|

Engine Type |

See Procedure |

|---|---|

|

2GR-FE |

See page |

|

1AR-FE |

See page |

Chassis

Chassis

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. INSPECT STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering wheel free play (See page

).

(b) Check the steering linkage for looseness ...

Inside Vehicle

Inside Vehicle

General Maintenance

GENERAL MAINTENANCE

CAUTION / NOTICE / HINT

These are maintenance and inspection items that are considered to be

the owner's responsibility.

The owner can do ...

Other materials about Toyota Venza:

Engine Immobiliser System Malfunction (B2799)

DESCRIPTION

This DTC is stored when one of the following occurs: 1) the ECM detects errors

in its own communications with the transponder key ECU assembly; 2) the ECM detects

errors in the communication lines; or 3) the ECU communication ID between the tr ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the navigation system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

0.1485

.gif)