Toyota Venza: Door Courtesy Switch Circuit

DESCRIPTION

When an additional transponder key is registered, the transponder key ECU assembly detects the front door courtesy light switch assembly (for driver side) open/close condition, and enters the key registration mode.

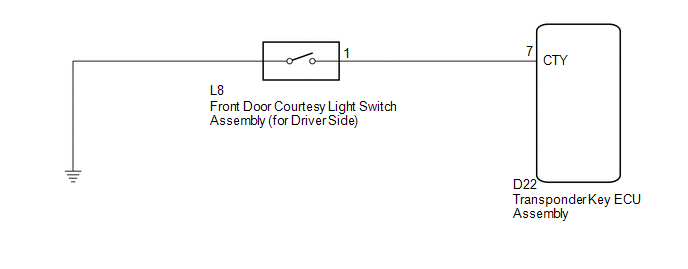

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder key ECU assembly is replaced, register the key and ECU communication

ID (See page .gif) ).

).

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (FRONT DOOR COURTESY LIGHT SWITCH CIRCUIT) |

|

(a) Disconnect the transponder key ECU assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

D22-7 (CTY) - Body ground |

Courtesy switch pushed (Door closed) |

10 kΩ or higher |

|

D22-7 (CTY) - Body ground |

Courtesy switch free (Door open) |

Below 1 Ω |

|

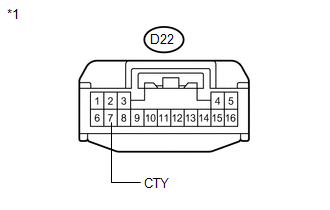

*1 |

Front view of wire harness connector (to Transponder Key ECU Assembly) |

| OK | .gif) |

REPLACE TRANSPONDER KEY ECU ASSEMBLY |

|

|

2. |

INSPECT FRONT DOOR COURTESY LIGHT SWITCH ASSEMBLY (for Driver Side) |

|

(a) Remove the front door courtesy light switch assembly (for driver

side) (See page |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

1 - Switch body |

Courtesy switch pushed (Door closed) |

10 kΩ or higher |

|

1 - Switch body |

Courtesy switch free (Door open) |

Below 1 Ω |

|

*1 |

Component without harness connected (Front Door Courtesy Light Switch Assembly (for Driver Side)) |

|

*2 |

Switch Body |

| OK | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSPONDER KEY ECU - FRONT DOOR COURTESY LIGHT SWITCH) |

| NG | .gif) |

REPLACE FRONT DOOR COURTESY LIGHT SWITCH ASSEMBLY (for Driver Side) |

Unmatched Encryption Code (B2794)

Unmatched Encryption Code (B2794)

DESCRIPTION

This DTC is stored when a key with an incomplete key code is inserted into the

ignition key cylinder.

DTC No.

DTC Detection Condition

Trouble Area

...

Security Indicator Light Circuit

Security Indicator Light Circuit

DESCRIPTION

The security indicator light blinks continuously due to a continuous signal received

from the transponder key ECU assembly while in the armed state.

WIRING DIAGRAM

CAUTION / NOTICE ...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR DOOR SCUFF PLATE LH

2. REMOVE REAR DOOR OPENING TRIM WEATHERSTRIP LH

3. REMOVE TONNEAU COVER ASSEMBLY (w/ Tonneau Cover)

4. REMOVE DECK BOARD ASSEMBLY

5. REMOVE NO. 3 DECK BOARD SUB-ASSEMBLY

6. REMOVE DECK ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL ECM

(a) Install the bracket to the ECM with the 5 screws.

(b) Install the ECM with the 3 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

...

Inspection

INSPECTION

PROCEDURE

1. INSPECT STEERING PAD SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

Specified Condition

...

0.1187

.gif)

.png)