Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FUEL SENDER GAUGE

.gif)

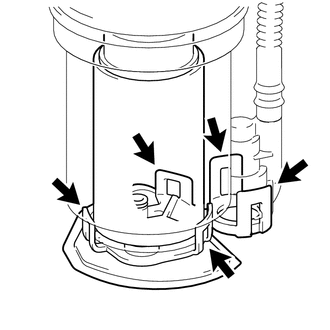

2. SEPARATE FUEL SUCTION PLATE SUB-ASSEMBLY

|

(a) Disconnect the fuel pump connector from the fuel suction plate. NOTICE: Do not damage the wire harness. |

|

|

(b) Using needle nose pliers, remove the E-ring. Text in Illustration

NOTICE: Do not disconnect the tube shown in the illustration when disassembling the fuel suction tube assembly with pump and gauge. Doing so will cause reassembly of the fuel suction tube assembly with pump and gauge to be impossible as the tube is welded to the plate. |

|

(c) Separate the fuel suction plate and remove the spring from the sub-tank.

3. REMOVE FUEL FILTER ASSEMBLY

|

(a) Disengage the 2 claws and remove the filter from the sub-tank. |

|

|

(b) Using a screwdriver with the tip taped, detach the claw of the jet pump nozzle. |

|

|

(c) Using a screwdriver with the tip taped, remove the jet pump from the sub-tank. |

|

|

(d) Remove the O-ring from the jet pump. Text in Illustration

|

|

4. REMOVE FUEL PUMP ASSEMBLY WITH FILTER

|

(a) Disengage the 5 claws on the filter and remove the fuel pump from the fuel filter. NOTICE:

HINT: If the fuel filter assembly is to be replaced, replace the fuel suction plate sub-assembly. |

|

|

(b) Disconnect the fuel pump connector from the fuel pump and then remove the fuel pump harness. |

|

|

(c) Remove the O-ring and spacer from the fuel pump. NOTICE: Be careful not to damage the sealing surface. HINT: If the O-ring still remains in the fuel filter, remove it using a wire tip (φ1 mm) that is formed as shown in the illustration. |

|

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the fuel pump assembly (See

page ).

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

(a) Discharge ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL PUMP ASSEMBLY WITH FILTER

(a) Inspect fuel pump resistance.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Other materials about Toyota Venza:

Brake Switch "A" Circuit (P0571)

DESCRIPTION

When the brake pedal is depressed, the stop light switch assembly sends a signal

to the ECM. When the ECM receives this signal, it cancels the cruise control. The

fail-safe function operates to enable normal driving even if there is a malfunct ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR POWER POINT SOCKET COVER

(a) Engage the 2 claws to install the rear power point socket cover.

2. INSTALL REAR POWER POINT SOCKET ASSEMBLY

(a) Engag ...

Calibration

CALIBRATION

1. ROTATION ANGLE SENSOR INITIALIZATION AND TORQUE SENSOR ZERO POINT CALIBRATION

NOTICE:

Clear the rotation angle sensor calibration value, initialize the rotation angle

sensor, and calibrate the torque sensor zero point if any of the followin ...

0.1171

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)