Toyota Venza: Compressor Lock Sensor Circuit (B1422/22)

SYSTEM DESCRIPTION

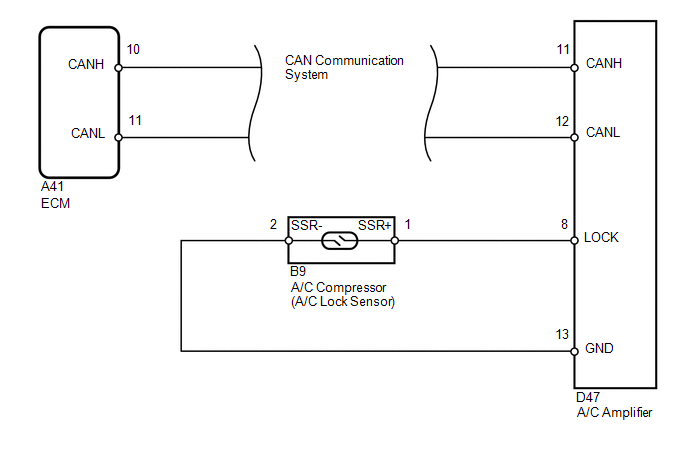

The ECM sends the engine speed signal to the A/C amplifier via CAN communication.

The A/C amplifier reads the difference between compressor speed and engine speed. When the difference becomes too large, the A/C amplifier determines that the compressor is locked, and turns the magnetic clutch off.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1422/22 |

Open or short in compressor lock sensor circuit |

|

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Use the Techstream to check if the CAN communication system is functioning normally.

|

Result |

Proceed to |

|---|---|

|

CAN DTC is not output |

A |

|

CAN DTC is output |

B |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

INSPECT A/C COMPRESSOR (A/C LOCK SENSOR) |

|

(a) Disconnect the A/C compressor connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

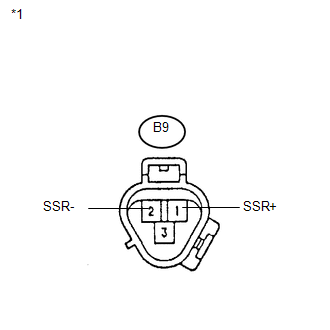

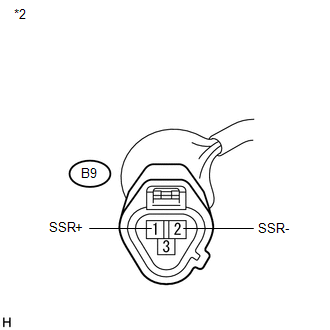

B9-1 (SSR+) - B9-2 (SSR-) |

20°C (68°F) |

160 to 320 Ω |

|

*1 |

Component without harness connected (A/C Compressor) |

| NG | .gif) |

REPLACE A/C COMPRESSOR (A/C LOCK SENSOR) |

|

|

3. |

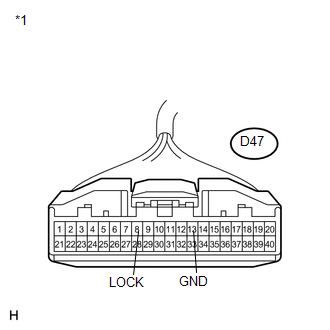

CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C LOCK SENSOR) |

|

(a) Disconnect the A/C amplifier connector. |

|

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

Result:

|

|

| A | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

| B | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| C | .gif) |

REPLACE A/C AMPLIFIER |

Evaporator Temperature Sensor Circuit (B1413/13)

Evaporator Temperature Sensor Circuit (B1413/13)

DESCRIPTION

The evaporator temperature sensor is installed on the evaporator in the air conditioning

unit to detect the cooled air temperature that has passed through the evaporator

and to contro ...

Room Temperature Sensor Circuit (B1411/11)

Room Temperature Sensor Circuit (B1411/11)

DESCRIPTION

The room temperature sensor is installed in the instrument panel. It detects

the cabin temperature to control the air conditioning AUTO mode. The resistance

of the room temperature se ...

Other materials about Toyota Venza:

Certification Ecu

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system.

N ...

Touch Panel Switch does not Function

PROCEDURE

1.

CHECK MULTI-DISPLAY

(a) Check if there is any foreign matter caught between the display and exterior

frame of the multi-display.

OK:

No foreign matter is caught between the display and exterior frame of the m ...

Terminals Of Ecu

TERMINALS OF ECU

NOTICE:

Turn the ignition switch off before measuring the resistances between

CAN bus main wires and between CAN bus branch wires.

Turn the ignition switch off before inspecting CAN bus wires for a ground

short.

After ...

0.1219

.gif)