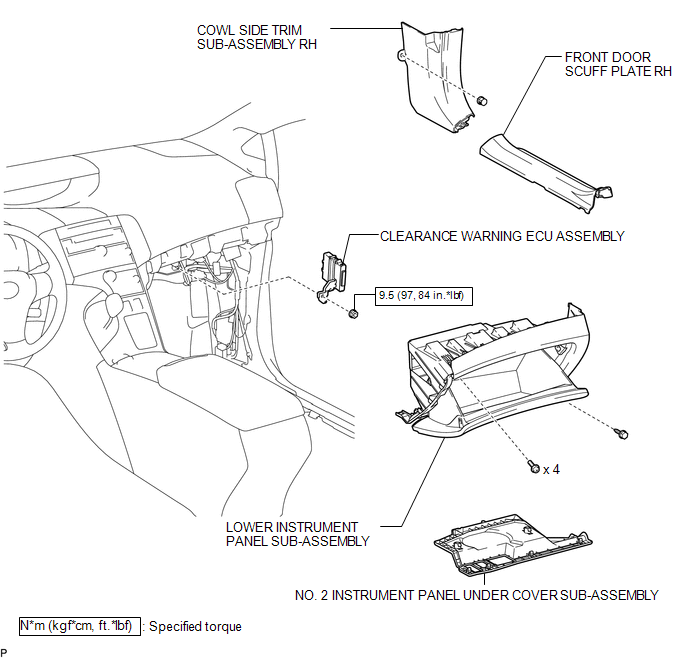

Toyota Venza: Clearance Warning Ecu

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE RH

.gif)

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY RH

.gif)

3. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

4. REMOVE LOWER INSTRUMENT PANEL SUB-ASSEMBLY

.gif)

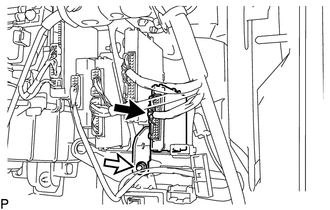

5. REMOVE CLEARANCE WARNING ECU ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the nut and clearance warning ECU assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL CLEARANCE WARNING ECU ASSEMBLY

(a) Install the clearance warning ECU assembly with the nut.

Torque:

9.5 N·m {97 kgf·cm, 84 in·lbf}

(b) Connect the connector.

2. INSTALL LOWER INSTRUMENT PANEL SUB-ASSEMBLY

.gif)

3. INSTALL NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

4. INSTALL COWL SIDE TRIM SUB-ASSEMBLY RH

.gif)

5. INSTALL FRONT DOOR SCUFF PLATE RH

.gif)

Clearance Warning Buzzer

Clearance Warning Buzzer

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE LH

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

3. REMOVE LOWER NO. 1 INSTRUMENT PANEL FIN ...

Other materials about Toyota Venza:

Adjustment

ADJUSTMENT

PROCEDURE

1. PRECAUTIONS AND WORK DESCRIPTION

(a) The U660E automatic transaxle does not have an oil filler tube and oil level

gauge. When adding fluid, add fluid through the refill hole on the transaxle case.

The fluid level can be adjusted ...

Precaution

PRECAUTION

1. WHEN DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following systems after the cable is reconnected.

System Name

See Proc ...

Short in Side Squib RH Circuit (B1820/55-B1823/55)

DESCRIPTION

The side squib RH circuit consists of the center airbag sensor assembly and front

seat side airbag assembly RH.

The center airbag sensor assembly uses this circuit to deploy the airbag when

deployment conditions are met.

These DTCs are store ...

0.1767