Toyota Venza: Ambient Temperature Sensor

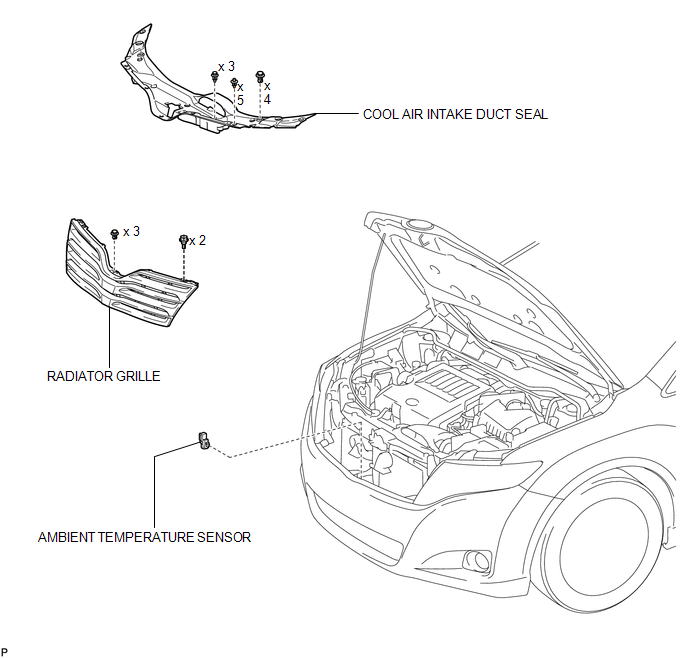

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT AMBIENT TEMPERATURE SENSOR

(a) Measure the resistance according to the value(s) in the table below.

.png)

.png)

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

10°C (50°F) |

3.00 to 3.73 kΩ |

|

1 - 2 |

15°C (59°F) |

2.45 to 2.88 kΩ |

|

1 - 2 |

20°C (68°F) |

1.95 to 2.30 kΩ |

|

1 - 2 |

25°C (77°F) |

1.60 to 1.80 kΩ |

|

1 - 2 |

30°C (86°F) |

1.28 to 1.47 kΩ |

|

1 - 2 |

35°C (95°F) |

1.00 to 1.22 kΩ |

|

1 - 2 |

40°C (104°F) |

0.80 to 1.00 kΩ |

|

1 - 2 |

45°C (113°F) |

0.65 to 0.85 kΩ |

|

1 - 2 |

50°C (122°F) |

0.50 to 0.70 kΩ |

|

1 - 2 |

55°C (131°F) |

0.44 to 0.60 kΩ |

|

1 - 2 |

60°C (140°F) |

0.36 to 0.50 kΩ |

NOTICE:

- Hold the sensor only by its connector. Touching the sensor may change the resistance value.

- When measuring, the sensor temperature must be the same as the ambient temperature.

HINT:

As the temperature increases, the resistance decreases (see the graph).

If the resistance is not as specified, replace the ambient temperature sensor.

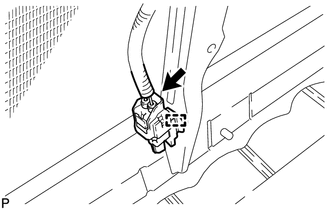

Text in Illustration|

*1 |

Component without harness connected (Ambient Temperature Sensor) |

|

*2 |

Sensing Portion |

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE RADIATOR GRILLE

.gif)

4. REMOVE AMBIENT TEMPERATURE SENSOR

|

(a) Disconnect the connector. |

|

(b) Disengage the clamp to remove the ambient temperature sensor.

Installation

INSTALLATION

PROCEDURE

1. INSTALL AMBIENT TEMPERATURE SENSOR

|

(a) Engage the clamp to install the ambient temperature sensor. |

|

(b) Connect the connector.

2. INSTALL RADIATOR GRILLE

.gif)

3. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR CONDITIONING UNIT ASSEMBLY

(a) Install the air conditioning unit assembly with the 3 nuts.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

NOTICE:

Tighten th ...

Blower Unit

Blower Unit

...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE SEAT ADJUSTER COVER CAP

(a) Remove the seat adjuster cover cap.

HINT:

Use the same procedure for the RH side and LH side.

2. REMOVE RECLINING POWER SEAT SWITCH ...

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT IG2 RELAY

(a) Remove the IG2 relay from the relay block.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Te ...

Personal/interior lights

► Front

On/off

The illuminated entry system is activated even if the light is turned off when

the personal/interior light main switch is in door position.

► Rear

On/off

The illuminated entry system is activated even if the light is turne ...

0.1675

.png)