Toyota Venza: Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

HINT:

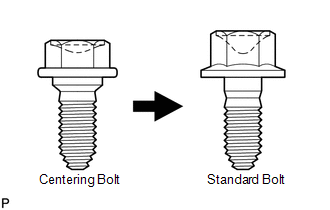

- Centering bolts are used to mount the hood hinge and hood lock. The hood and hood lock cannot be adjusted with the centering bolts installed. Substitute the centering bolts with standard bolts when making adjustments.

- Specified torque for standard bolts is shown in the standard bolt chart

(See page

.gif) ).

).

PROCEDURE

1. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

2. REMOVE RADIATOR GRILLE

.gif)

3. ADJUST HOOD SUB-ASSEMBLY

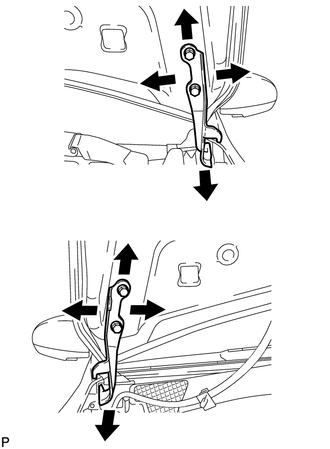

(a) Horizontally and vertically adjust the hood.

|

(1) Loosen the 4 hinge bolts of the hood. |

|

(2) Adjust the clearance between the hood and front fender by moving the hood.

(3) Tighten the 4 hinge bolts after the adjustment.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

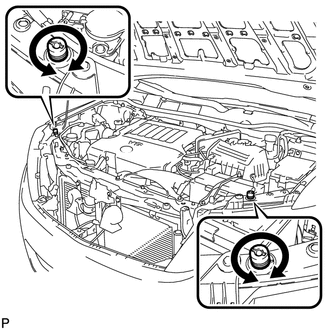

(b) Adjust the height of the front end of the hood using the cushion rubbers.

|

(1) Adjust the 2 cushion rubbers so that the heights of the hood and fender are aligned. HINT: Raise or lower the front end of the hood by turning the 2 cushion rubbers. |

|

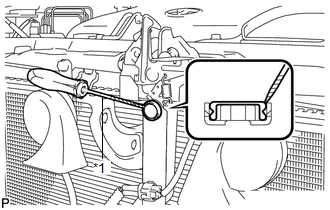

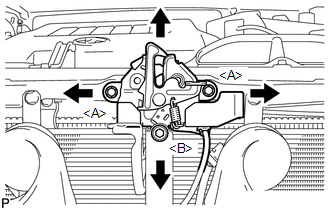

(c) Adjust the hood lock.

|

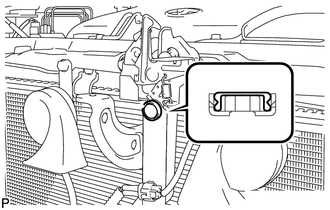

(1) Using a screwdriver, remove the hood lock nut cap. Text in Illustration

HINT: Tape the screwdriver tip before use. |

|

|

(2) Loosen the 3 bolts. |

|

(3) Tighten the bolts after the adjustment.

Torque:

<A> :

7.5 N·m {77 kgf·cm, 66 in·lbf}

Torque:

<B> :

8.0 N·m {82 kgf·cm, 71 in·lbf}

(4) Check that the striker can engage with the hood lock smoothly.

|

(d) Install a new hood lock nut cap. |

|

4. INSTALL RADIATOR GRILLE

.gif)

5. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas *1 through *4 are within each

standard range.

Standard Clearance

Area ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. CONNECT WASHER HOSE ASSEMBLY

(a) Engage the 5 clips and connect the washer hose assembly.

2. INSTALL FRONT WASHER ...

Other materials about Toyota Venza:

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC (CHECK USING TECHSTREAM)

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Navigation System / Trouble

Codes.

(e) Chec ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. REMOVE DECK SIDE TRIM

(a) Disengage the 5 claws, and ...

If the shift lever cannot be shifted from “P”

If the shift lever cannot be shifted with your foot on the brake, there may

be a problem with the shift lock system (a system to prevent accidental operation

of the shift lever). Have the vehicle inspected by your Toyota dealer immediately.

The following ...

0.1562