Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

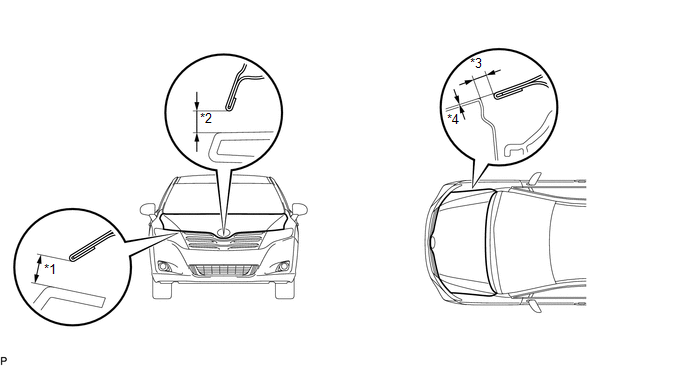

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas *1 through *4 are within each standard range.

Standard Clearance

Standard Clearance

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

*1 |

6.9 to 9.9 mm (0.272 to 0.390 in.) |

*3 |

2.8 to 5.8 mm (0.110 to 0.228 in.) |

|

*2 |

7.6 to 10.6 mm (0.299 to 0.417 in.) |

*4 |

-1.5 to 1.5 mm (-0.0591 to 0.0591 in.) |

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE HOOD TO RADIATOR SUPPORT SEAL

(a) Using a clip remover, disengage the 10 clips and remove the hood

to radiator support seal.

...

Adjustment

Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

HINT:

Centering bolts are used to mount the hood hinge and hood lock. The

hood and hood lock cannot be adjusted with the centering bolts installed. ...

Other materials about Toyota Venza:

Vehicle Speed Signal Error (Test Mode DTC) (C2191/91)

DESCRIPTION

The tire pressure warning ECU receives a vehicle speed signal from the combination

meter. This DTC is stored upon entering signal check mode (test mode), and cleared

when a vehicle speed signal of 20 km/h (12 mph) is detected for 3 seconds or ...

Short in Front Passenger Side Squib Circuit (B1805/52-B1808/52)

DESCRIPTION

The front passenger side squib circuit consists of the center airbag sensor assembly

and front passenger airbag assembly.

The center airbag sensor assembly uses this circuit to deploy the airbag when

deployment conditions are met.

These DTCs ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) The power window control system data can be read from the Data Link Connector

3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the Techstream

to check for malfunctions and perform repairs.

2. C ...

0.1191