Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

4. REMOVE V-RIBBED BELT

HINT:

See page .gif)

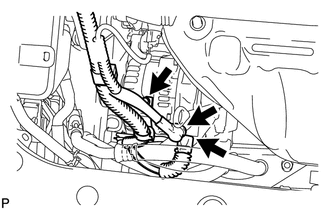

5. REMOVE WIRE HARNESS CLAMP BRACKET

(a) Detach the wire harness clamp from the clamp bracket.

(b) Remove the bolt and clamp bracket.

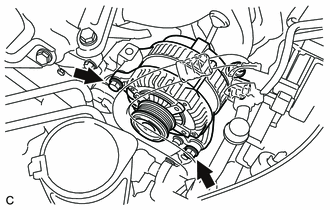

6. REMOVE GENERATOR ASSEMBLY

|

(a) Disconnect the generator connector. |

|

(b) Remove the terminal cap.

(c) Remove the nut and disconnect the generator wire.

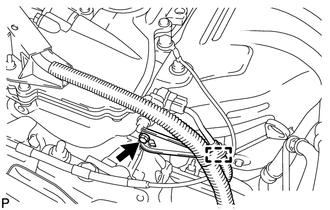

(d) Remove the bolt and wire harness clamp bracket.

|

(e) Remove the 2 bolts and generator. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR PULLEY CAP

(a) Using a screwdriver, puncture the center of the generator pulley

cap and pry it off.

NOTICE:

Do not reuse the generator ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

HOW TO PROCEED WITH TROUBLESHOOTING

1. OPERATION FLOW

HINT:

Perform troubleshooting in accordance with the procedure below. The following

is an outline of basic troubleshooting procedure. Confirm the troubleshooting procedure

for the circuit you are wor ...

Repair

REPAIR

PROCEDURE

1. REPAIR INTAKE VALVE SEAT

NOTICE:

Repair the seat while checking the seating position.

Keep the lip free of foreign matter.

Take off the cutter gradually to make the intake valve seat smooth.

(a) Usin ...

Control Module Communication Bus OFF (U0073/86,U0100/85,U0129/83)

DESCRIPTION

The AWD control ECU inputs the signals sent from the ECM and skid control

ECU via the CAN communication system.

When DTCs indicating a CAN communication system malfunction are output,

repair the CAN communication system before r ...

0.1155