Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

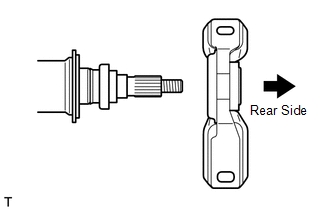

1. INSTALL NO. 1 CENTER SUPPORT BEARING ASSEMBLY

|

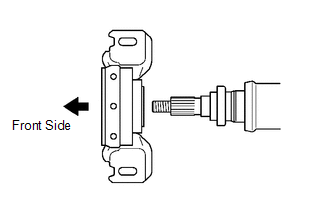

(a) Set the No. 1 center support bearing on the intermediate shaft as shown in the illustration. NOTICE: Make sure to install the bearing in the correct position. |

|

(b) Install a new washer to the intermediate shaft.

|

(c) Align the matchmarks on the universal joint flange and intermediate shaft and place the flange on the shaft. Text in Illustration

|

|

|

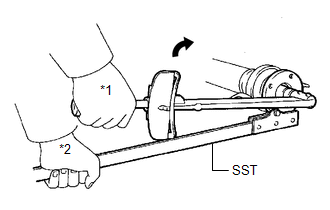

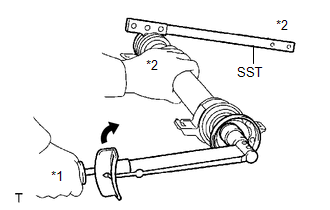

(d) Using SST to hold the universal joint flange, press the No. 1 center support bearing assembly into position by tightening a new nut and washer. SST: 09330-00021 Torque: 182 N·m {1851 kgf·cm, 134 ft·lbf} Text in Illustration

|

|

(e) Loosen the nut.

(f) Tighten the nut again.

Torque:

69 N·m {701 kgf·cm, 51 ft·lbf}

|

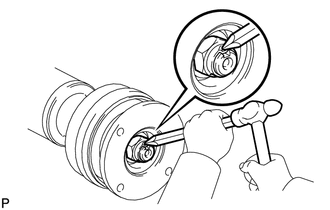

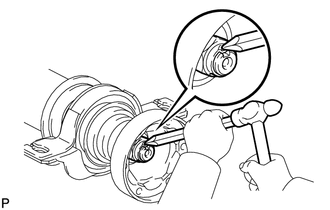

(g) Using a chisel and a hammer, stake the nut. |

|

2. INSTALL NO. 2 CENTER SUPPORT BEARING ASSEMBLY

|

(a) Set the No. 2 center support bearing on the intermediate shaft as shown in the illustration. NOTICE: Make sure to install the bearing in the correct position. |

|

(b) Install a new washer to the intermediate shaft.

|

(c) Align the matchmarks on the universal joint flange and intermediate shaft, and place the flange on the shaft. Text in Illustration

|

|

|

(d) Using SST to hold the universal joint flange, press the No. 2 center support bearing assembly into position by tightening a new nut and washer. SST: 09330-00021 Torque: 182 N·m {1851 kgf·cm, 134 ft·lbf} Text in Illustration

|

|

(e) Loosen the nut.

(f) Tighten the nut again.

Torque:

69 N·m {701 kgf·cm, 51 ft·lbf}

|

(g) Using a chisel and a hammer, stake the nut. |

|

3. INSTALL INTERMEDIATE SHAFT

|

(a) Align the matchmarks on the intermediate shaft and rear propeller shaft, and then install 2 washers and 6 bolts. Text in Illustration

|

|

(b) Using a hexagon wrench (6 mm), tighten the 6 bolts with 2 washers temporarily.

4. INSTALL PROPELLER SHAFT

(a) Align the matchmarks on the propeller shaft and the universal joint flange.

|

(b) Install the propeller shaft to the front flange with the 4 bolts, 4 washers and 4 nuts. Torque: 74 N·m {750 kgf·cm, 55 ft·lbf} NOTICE:

|

|

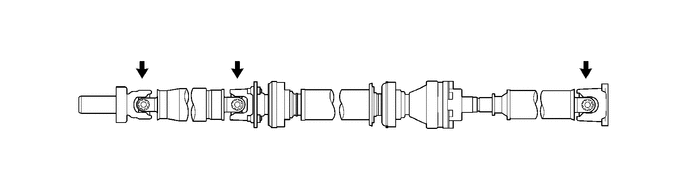

(c) Check that each joint of the propeller with center bearing shaft assembly is facing the direction shown in the illustration.

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Remove SST from the transfer.

SST: 09325-20010

...

Propeller Shaft System

Propeller Shaft System

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symp ...

Other materials about Toyota Venza:

Rocker Panel Moulding

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT FENDER OUTSIDE MOULDING

2. REMOVE NO. 2 ROCKER PANEL MOULDING PROTECTOR

3. REMOVE REAR ROCKER PANEL MOULDING END COVER

4. REMOVE BODY ROCKER PANEL MOULDING ASS ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT COMPRESSOR FOR METALLIC SOUND

(a) Check if there is abnormal metallic sound from the A/C compressor (compressor

with pulley) when the A/C switch is on and the A/C compressor (compressor with pulley)

operates.

...

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY)

(a) Disconnect the 2C, 2F and 2K main body ECU (driver side junction block assembly)

connectors.

(b) Measure the voltage and resistance according to the value(s) in the table ...

0.1567

.png)

.png)

.png)

.png)