Toyota Venza: Security Indicator Light Circuit

DESCRIPTION

The security indicator light blinks continuously due to a continuous signal received from the transponder key ECU assembly while in the armed state.

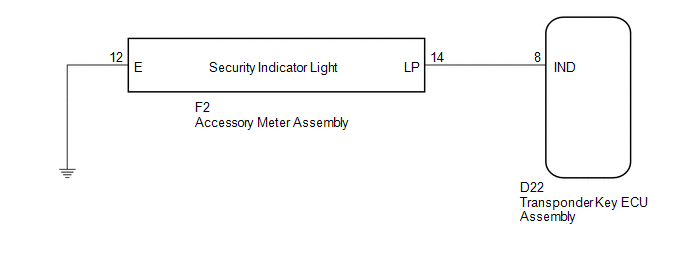

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder key ECU assembly is replaced, register the key and ECU communication

ID (See page .gif) ).

).

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Immobiliser / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Immobiliser (Transponder Key ECU Assembly)|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Security Indicator |

Security indicator light |

ON/OFF |

- |

OK:

The security indicator turns on and off according to operation via the Techstream.

| OK | .gif) |

REPLACE TRANSPONDER KEY ECU ASSEMBLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (TRANSPONDER KEY ECU - ACCESSORY METER) |

(a) Disconnect the transponder key ECU assembly connector.

|

(b) Disconnect the accessory meter assembly connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D22-8 (IND) - F2-14 (LP) |

Always |

Below 1 Ω |

|

D22-8 (IND) - Body ground |

Always |

10 kΩ or higher |

|

F2-14 (LP) - Body ground |

Always |

10 kΩ or higher |

|

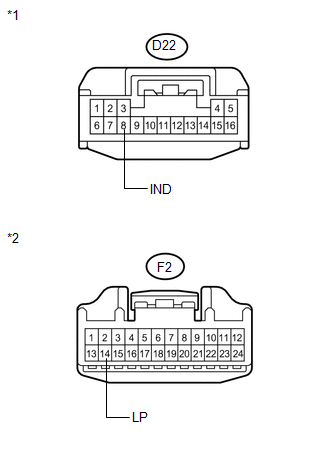

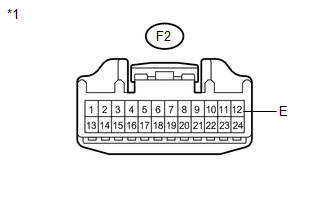

*1 |

Front view of wire harness connector (to Transponder Key ECU Assembly) |

|

*2 |

Front view of wire harness connector (to Accessory Meter Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (ACCESSORY METER - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Door Courtesy Switch Circuit

Door Courtesy Switch Circuit

DESCRIPTION

When an additional transponder key is registered, the transponder key ECU assembly

detects the front door courtesy light switch assembly (for driver side) open/close

condition, and en ...

ECU Power Source Circuit

ECU Power Source Circuit

DESCRIPTION

This circuit provides power to operate the transponder key ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder key ECU assembly is replaced, register the ...

Other materials about Toyota Venza:

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is stored during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" below.

1. TRANSPONDER KEY ECU DIAGNOSTIC TROUBLE CODE CHART

Trans ...

Road Test

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem analysis, try to reproduce the

symptoms. If the problem is that the transaxle does not shift up, shift down, or

the shift point is too high or too low, conduct the ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL STUD BOLT (for LH Side)

(a) Install the stud bolt.

Torque:

17 N·m {173 kgf·cm, 13 ft·lbf}

2. INSTALL STUD BOLT (for RH Side)

HINT:

Perform the same proc ...

0.1184

.gif)