Toyota Venza: ECU Power Source Circuit

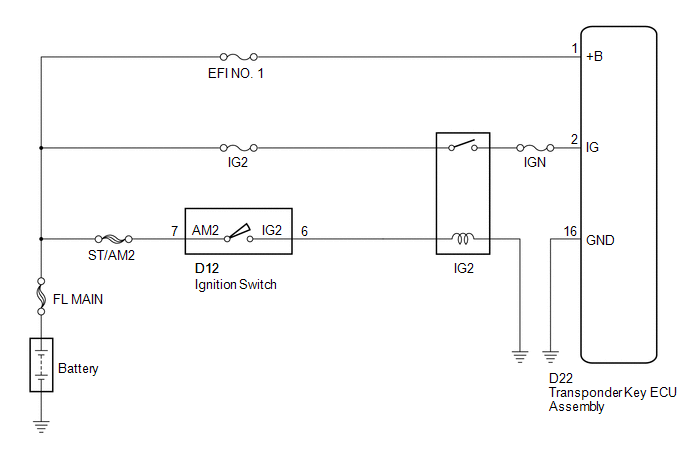

DESCRIPTION

This circuit provides power to operate the transponder key ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder key ECU assembly is replaced, register the key and ECU communication

ID (See page .gif) ).

).

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (TRANSPONDER KEY ECU - BATTERY AND BODY GROUND) |

|

(a) Disconnect the transponder key ECU assembly connector. |

|

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D22-1 (+B) - Body ground |

Always |

11 to 14 V |

|

D22-2 (IG) - Body ground |

Ignition switch off |

Below 1 V |

|

D22-2 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D22-16 (GND) - Body ground |

Always |

Below 1 Ω |

|

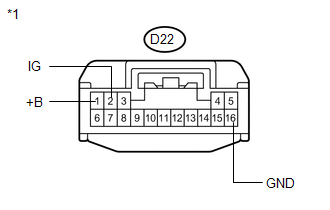

*1 |

Front view of wire harness connector (to Transponder Key ECU Assembly) |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR, OR REPLACE FUSE |

Security Indicator Light Circuit

Security Indicator Light Circuit

DESCRIPTION

The security indicator light blinks continuously due to a continuous signal received

from the transponder key ECU assembly while in the armed state.

WIRING DIAGRAM

CAUTION / NOTICE ...

Diagnosis Circuit

Diagnosis Circuit

DESCRIPTION

This circuit is used to read the DTCs that are output from the transponder key

ECU assembly with the Techstream.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the transponder ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSFER ASSEMBLY

(a) Install the transfer assembly to the automatic transaxle assembly

with 2 new bolts and the 6 nuts.

Torque:

69 N·m {700 kgf·cm, 51 ft·lbf}

NOTICE:

Install the ...

Power Back Door cannot be Opened or Closed Using the Power Back Door Switch

DESCRIPTION

When the power back door cannot be opened or closed using the power back door

control switch, one of the following may be malfunctioning: 1) power back door control

switch circuit, 2) power back door ECU (power back door motor unit) or 3) main ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

Parameters listed in the chart may not be exactly the same as your readings due

to the type of instrument or other factors. If a trouble code is displayed during

the DTC check, inspect the trouble areas listed for that ...

0.1387