Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

3. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

4. REMOVE NO. 1 ENGINE UNDER COVER

5. REMOVE NO. 2 ENGINE UNDER COVER

6. DRAIN ENGINE COOLANT

.gif)

7. REMOVE V-RIBBED BELT

HINT:

See page .gif)

8. REMOVE WIRE HARNESS CLAMP BRACKET

.gif)

9. REMOVE GENERATOR ASSEMBLY

.gif)

10. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

.gif)

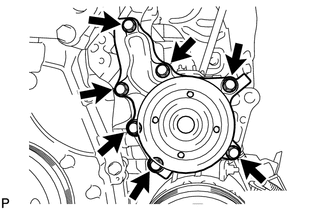

11. REMOVE WATER PUMP ASSEMBLY

|

(a) Remove the 7 bolts, water pump and water pump gasket. |

|

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FOR COOLANT LEAK

HINT:

The sliding surface inside the engine water pump assembly is lubricated

by engine coolant. As some engine coolant is d ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL WATER PUMP ASSEMBLY

(a) Install a new gasket and the water pump with the 7 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Readiness Monitor Drive Pattern

READINESS MONITOR DRIVE PATTERN

1. PURPOSE OF READINESS TESTS

The On-Board Diagnostic (OBD II) system is designed to monitor the performance

of emission related components, and indicate any detected abnormalities

using DTCs (Diagnostic Trouble ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.2094