Toyota Venza: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL REAR STRUT ROD ASSEMBLY (for 2WD)

|

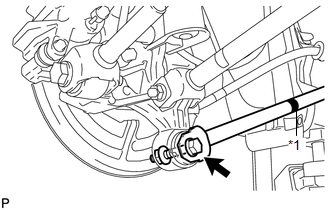

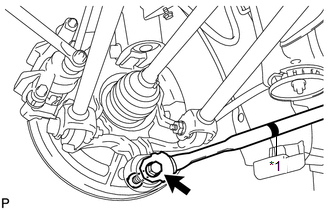

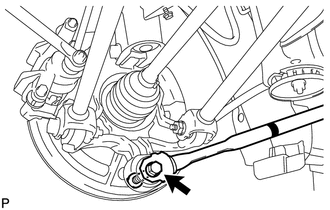

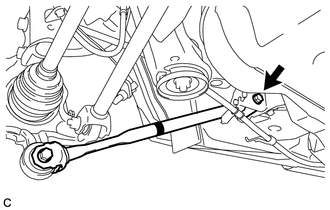

(a) Temporarily install the rear strut rod assembly to the rear axle carrier sub-assembly with the bolt and the nut. Text in Illustration

NOTICE:

|

|

|

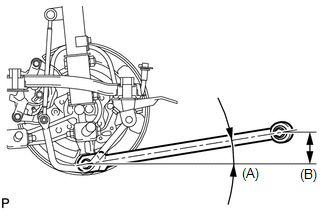

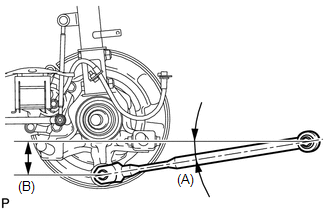

(b) Set the rear strut rod assembly in the tightening position shown in the illustration. Standard angle (A): 9°54' (9.9°) Standard length (B): 83.9 mm (3.30 in.) |

|

|

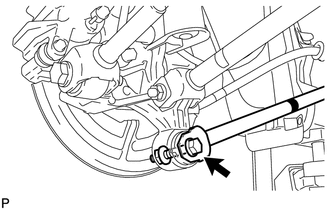

(c) Fully tighten the bolt in the tightening position. Torque: 80 N·m {816 kgf·cm, 59 ft·lbf} |

|

|

(d) Temporarily install the rear strut rod assembly to the body with the bolt and the nut. |

|

|

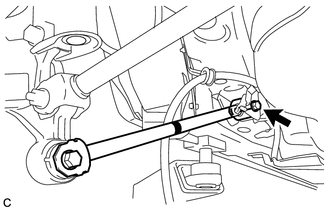

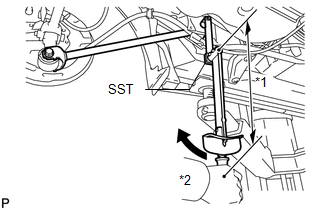

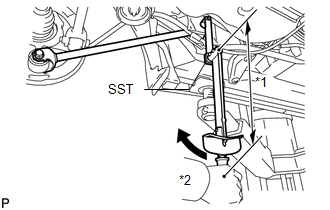

(e) Using SST and a socket wrench (17 mm), fully tighten the bolt in the rebound position. Text in Illustration

SST: 09961-00950 Torque: Specified Tightening Torque : 80 N·m {816 kgf·cm, 59 ft·lbf} NOTICE:

HINT:

|

|

2. INSTALL REAR STRUT ROD ASSEMBLY (for AWD)

|

(a) Temporarily install the rear strut rod assembly to the rear axle carrier sub-assembly with the bolt and the nut. Text in Illustration

NOTICE:

|

|

|

(b) Set the rear strut rod assembly in the tightening position shown in the illustration. Standard angle (A): 9°3' (9.04°) Standard length (B): 78.3 mm (3.08 in.) |

|

|

(c) Fully tighten the bolt in the tightening position. Torque: 80 N·m {816 kgf·cm, 59 ft·lbf} |

|

|

(d) Temporarily install the rear strut rod assembly to the body with the bolt and the nut. |

|

|

(e) Using SST and a socket wrench (17 mm), fully tighten the bolt in the rebound position. Text in Illustration

SST: 09961-00950 Torque: Specified Tightening Torque : 80 N·m {816 kgf·cm, 59 ft·lbf} NOTICE:

HINT:

|

|

3. INSTALL NO. 3 PARKING BRAKE CABLE ASSEMBLY

|

(a) Install the No. 3 parking brake cable assembly with the bolt. Torque: 6.0 N·m {61 kgf·cm, 53 in·lbf} NOTICE: Do not twist the No. 3 parking brake cable assembly when installing it. |

|

4. INSTALL REAR WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

5. STABILIZE SUSPENSION

(a) Lower the vehicle to the ground.

(b) Bounce the vehicle up and down at the corners to stabilize the rear suspension.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPAR ...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

3. REMOVE COOL AIR ...

Pressure Control Solenoid "A" Electrical (Shift Solenoid Valve SL1) (P0748)

DESCRIPTION

Changing from 1st to 6th is performed by the TCM turning shift solenoid valves

SL1, SL2, SL3, SL4 and SL on and off. If an open or short circuit occurs in any

of the shift solenoid valves, the TCM controls the remaining normal shift solenoid

...

0.1151

.gif) ).

).

.png)