Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Do not remove the oil pump or oil pump relief valve from the timing chain cover sub-assembly.

PROCEDURE

1. INSTALL ENGINE ON ENGINE STAND

(See page .gif) )

)

2. REMOVE IGNITION COIL ASSEMBLY

.gif)

3. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

.gif)

4. REMOVE CRANKSHAFT POSITION SENSOR

.gif)

5. REMOVE CRANKSHAFT PULLEY

.gif)

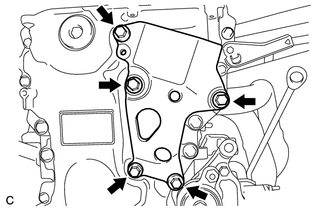

6. REMOVE ENGINE MOUNTING BRACKET RH

|

(a) Remove the 5 bolts and engine mounting bracket RH. |

|

7. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

.gif)

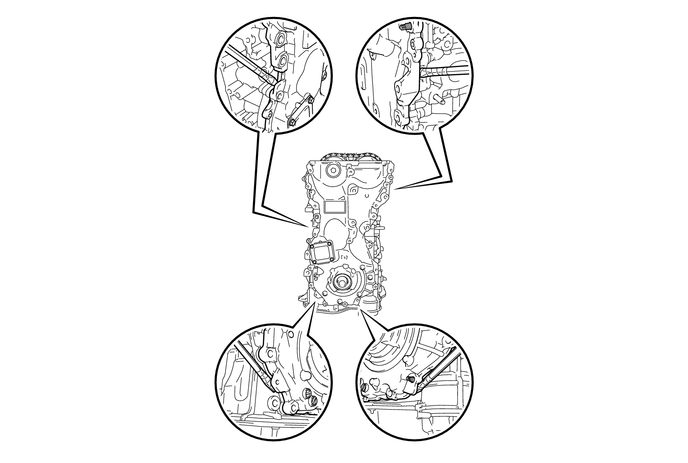

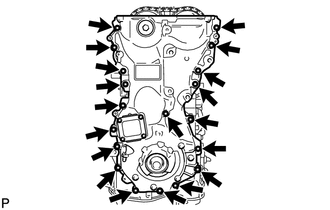

8. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

|

(a) Remove the 17 bolts and 2 nuts. |

|

(b) Remove the timing chain cover sub-assembly by prying between the timing chain cover sub-assembly and cylinder head, camshaft housing, cylinder block and stiffening crankcase with a screwdriver as shown in the illustration.

NOTICE:

Be careful not to damage the contact surfaces of the cylinder head, camshaft housing, cylinder block, stiffening crankcase and timing chain cover sub-assembly.

HINT:

Tape the screwdriver tip before use.

|

(c) Remove the 2 oil pump gaskets and oil hole cover gasket from the stiffening crankcase. |

|

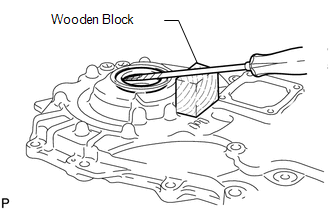

9. REMOVE TIMING CHAIN COVER OIL SEAL

|

(a) Using a screwdriver and wooden block, pry out the timing chain cover oil seal. NOTICE: Do not damage the surface of the timing chain cover oil seal press fit hole. HINT: Tape the screwdriver tip before use. |

|

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

(a) Apply a light coat of engine oil to 2 new oil pump gaskets and new

oil hole cover gasket.

...

1ar-fe Starting

1ar-fe Starting

...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT STEERING PAD SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

Specified Condition

...

Satellite Radio Broadcast cannot be Received

CAUTION / NOTICE / HINT

NOTICE:

Some satellite radio broadcasts require payment. A contract must be made between

a satellite radio company and the user. If the contract expires, it will not be

possible to listen to the broadcast.

PROCEDURE

1 ...

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM

HINT:

The items in the table below can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to m ...

0.1214

.png)