Toyota Venza: Pressure Control Solenoid "D" Electrical (Shift Solenoid Valve SLT) (P2716)

DESCRIPTION

Refer to DTC P2714 (See page .gif) ).

).

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

P2716 |

Open or short is detected in shift solenoid valve SLT circuit for 1 second or more while driving (1-trip detection logic). |

|

MONITOR DESCRIPTION

When an open or short in the linear solenoid valve (SLT) circuit is detected, the TCM interprets this as a fault. The TCM will turn on the MIL and store the DTC.

MONITOR STRATEGY

|

Related DTCs |

P2716: Shift solenoid valve SLT/Range check |

|

Required sensors/Components |

Shift solenoid valve SLT |

|

Frequency of operation |

Continuous |

|

Duration |

1 sec. |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

ALL:|

The monitor will run whenever this DTC is not present |

None |

|

Solenoid current cut status |

Not cut |

|

Ignition switch |

ON |

|

Starter |

OFF |

|

Battery voltage |

12 V or more |

|

Target current |

1 A |

|

Battery voltage |

10 V or more and less than 12 V |

|

Target current |

Less than 0.75 A |

|

Battery voltage |

8 V or more |

|

Target current |

1 A |

|

Battery voltage |

11 V or more |

|

Target current |

1 A or more |

|

Battery voltage |

11 V or more |

|

Target current |

0.1 A or more |

|

Target voltage - Last target voltage |

Less than 0.0000191 V |

TYPICAL MALFUNCTION THRESHOLDS

Malfunction (A) and (B):|

Output duty cycle |

100% or more |

|

Output duty cycle |

0% or less |

|

Solenoid voltage monitor |

No signal |

|

Target voltage - Average of monitor voltage |

0.035 V or more |

COMPONENT OPERATING RANGE

|

Output duty cycle |

Less than 100% |

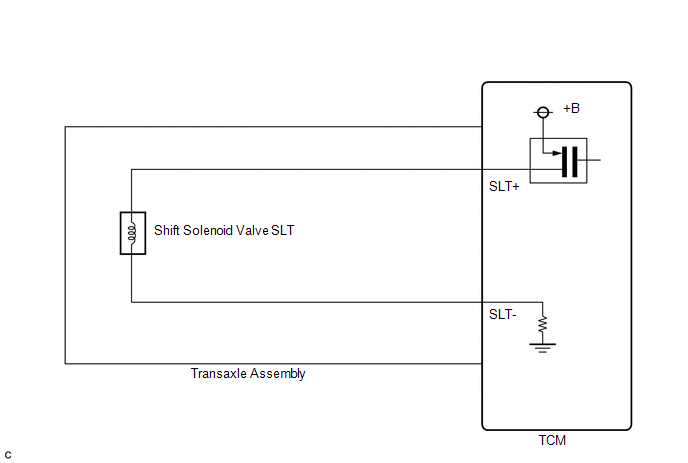

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Perform the universal trip to clear permanent DTCs (See page

.gif) ).

).

PROCEDURE

|

1. |

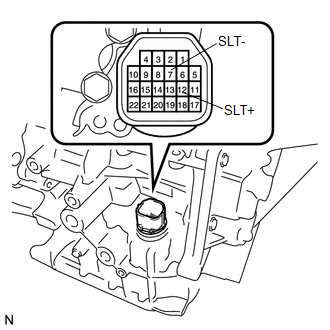

INSPECT TRANSMISSION WIRE (SLT) |

|

(a) Remove the TCM from the transaxle. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

12 (SLT+) - 7 (SLT-) |

20°C (68°F) |

5.0 to 5.6 Ω |

|

12 (SLT+) - Body ground |

Always |

10 kΩ or higher |

|

7 (SLT-) - Body ground |

Always |

10 kΩ or higher |

|

12 (SLT+) - All other terminals except 7 (SLT-) |

Always |

10 kΩ or higher |

|

7 (SLT-) - All other terminals except 12 (SLT+) |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE TCM |

|

|

2. |

INSPECT SHIFT SOLENOID VALVE SLT |

|

(a) Remove shift solenoid valve SLT. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

20°C (68°F) |

5.0 to 5.6 Ω |

|

*1 |

Shift Solenoid Valve SLT |

(c) Connect a battery positive (+) lead with a 21 W bulb to terminal 2 and a negative (-) lead to terminal 1 of the solenoid valve connector. Then check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| OK | .gif) |

REPLACE TRANSMISSION WIRE |

| NG | .gif) |

REPLACE SHIFT SOLENOID VALVE SLT |

Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical

(Shift Solenoid Valve SLU) (P2759)

Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical

(Shift Solenoid Valve SLU) (P2759)

DESCRIPTION

The amount of current flow to the solenoid is controlled by the duty ratio of

the TCM output signal. The higher the duty ratio becomes, the higher the lock-up

hydraulic pressure becom ...

Torque Converter Clutch Pressure Control Solenoid Performance (Shift Solenoid

Valve SLU) (P2757)

Torque Converter Clutch Pressure Control Solenoid Performance (Shift Solenoid

Valve SLU) (P2757)

SYSTEM DESCRIPTION

The TCM uses the signals from the throttle position sensor, air-flow meter, turbine

(input) speed sensor, output speed sensor and crankshaft position sensor to monitor

the enga ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT TIE ROD ASSEMBLY LH

(a) Secure the tie rod assembly LH in a vise.

(b) Install the nut to the stud bolt.

(c) Flip the ball joint back and forth 5 times.

(d) Set a to ...

Seat Heater Control

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL SEAT HEATER CONTROL SUB-ASSEMBLY

(a) Engage the clamp and install the seat heater control sub-assembly.

(b ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT STEERING WHEEL FREE PLAY

(a) Stop the vehicle and position the front wheels straight ahead.

(b) Gently turn the steering wheel right and left, and check the steering wheel

free play.

Maximum free play:

30 mm ...

0.152

.gif)

.png)