Toyota Venza: PIG Power Supply Voltage Malfunction (C1552)

DESCRIPTION

When a problem occurs in the power steering system, the power source relay circuit is shut off to stop the power assist.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1552 |

PIG power source circuit malfunction inside ECU |

|

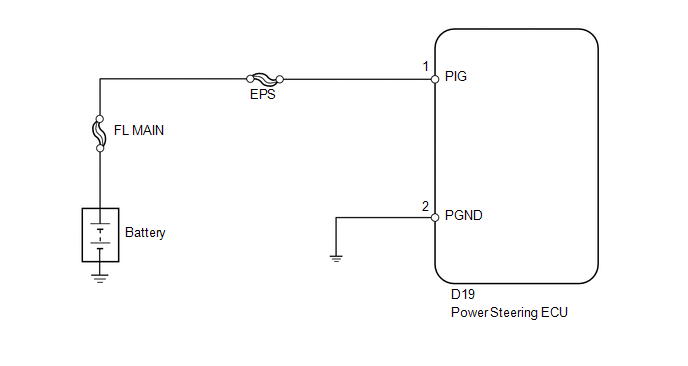

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- If the power steering ECU has been replaced with a new one, perform

the rotation angle sensor initialization and torque sensor zero point calibration

(See page

.gif) ).

). - Inspection the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (PIG POWER SUPPLY) |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Start the engine.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / EMPS / Data List.

(f) Select the items "PIG Power Supply" in the Data List and read the value displayed on the Techstream.

EMPS|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

PIG Power Supply |

Power source voltage to active motor/ Min.: 0 V Max.: 20.1531 V |

11 to 14 V |

The engine is running and power steering is operating. |

OK:

Normal condition value is displayed the Techstream.

| OK | .gif) |

REPLACE POWER STEERING ECU |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER STEERING ECU - BATTERY AND BODY GROUND) |

|

(a) Disconnect the connector from the power steering ECU. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D19-1 (PIG) - Body ground |

Always |

11 to 14 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D19-2 (PGND) - Body ground |

Always |

Below 1 Ω |

|

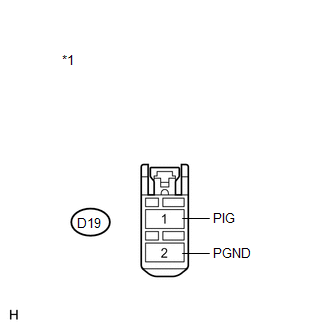

*1 |

Front view of wire harness connector (to Power Steering ECU) |

| OK | .gif) |

REPLACE POWER STEERING ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Assist Map Number Mismatch (C1582)

Assist Map Number Mismatch (C1582)

DESCRIPTION

When an incorrect ECM or brake actuator assembly (skid control ECU) is installed

after the assist map has been recorded in the power steering ECU, then DTC C1582

is stored because the ...

Assist Map Number Un-Writing (C1581)

Assist Map Number Un-Writing (C1581)

DESCRIPTION

The power steering ECU stores this DTC when it determines that the assist map

is not written in the ECU.

HINT:

The assist map is data written in the power steering ECU to control the ...

Other materials about Toyota Venza:

Speaker Circuit

DESCRIPTION

If there is a short in a speaker circuit, the radio and display receiver

assembly detects it and stops output to the speakers.

Thus sound cannot be heard from the speakers even if there is no malfunction

in the radio and display ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY

(a) Inspect the shift lock operation.

(1) Move the shift lever to P.

(2) Turn the ignition switch off.

(3) Check that the shift lever cannot be moved from P to any other position ...

Yaw Rate Sensor Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Yaw Rate Sensor Communication Stop Mode

"Yaw Rate/Decelerate Sensor" is not displayed on "CAN Bus Check"

screen o ...

0.1356

.gif)