Toyota Venza: Purge Valve

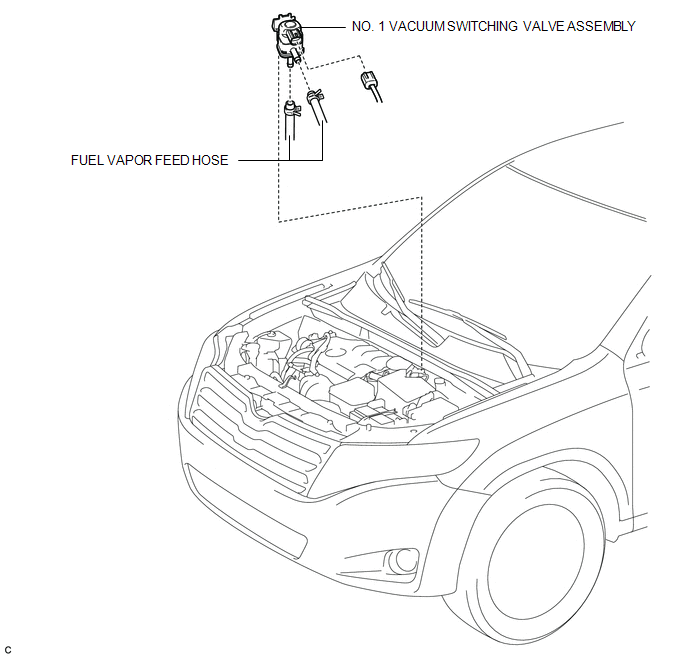

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

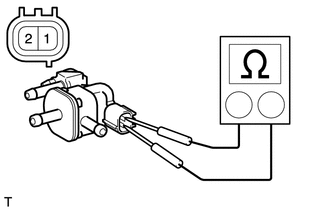

1. INSPECT NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 vacuum switching valve assembly. |

|

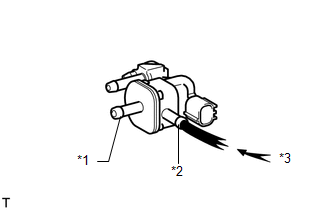

(b) Check the operation of the No. 1 vacuum switching valve assembly.

|

(1) Check that air does not flow from port F when air is applied to port E. Text in Illustration

|

|

|

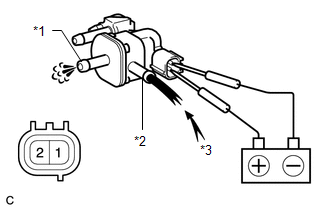

(2) Apply battery voltage to the connector, and check the VSV operation. Text in Illustration

OK:

If the result is not as specified, replace the No. 1 vacuum switching valve assembly. |

|

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

|

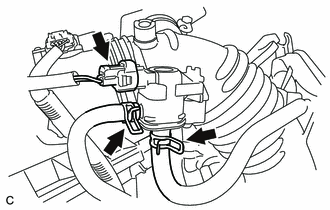

(a) Disconnect the connector and 2 fuel vapor feed hoses. |

|

|

(b) Remove the No. 1 vacuum switching valve assembly. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

|

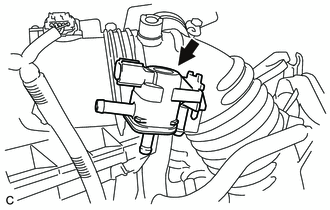

(a) Install the No. 1 vacuum switching valve assembly. |

|

|

(b) Connect the connector and 2 fuel vapor feed hoses. |

|

Pcv Valve

Pcv Valve

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INTAKE MANIFOLD

(a) Remove the intake manifold (See page ).

2. REMOVE VENTILATION VALVE SUB-ASSEMBLY

( ...

Other materials about Toyota Venza:

Terminals Of Ecu

TERMINALS OF ECU

NOTICE:

Turn the ignition switch off before measuring the resistances between

CAN bus main wires and between CAN bus branch wires.

Turn the ignition switch off before inspecting CAN bus wires for a ground

short.

After ...

Terminals Of Ecu

TERMINALS OF ECU

1. STEERING LOCK ECU (STEERING LOCK ACTUATOR ASSEMBLY)

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

Specified Condition

D17-1 (GND) - Body ground

...

Rear Center Seat Inner Belt Assembly

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR SEAT HEADREST ASSEMBLY

2. REMOVE REAR SEAT INNER TRACK BRACKET COVER

3. REMOVE REAR SEAT OUTER TRACK BRACKET COVER

4. DISCONNECT REAR SEAT NO. 2 RECLINING CONTR ...

0.1475

.png)

.png)