Toyota Venza: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

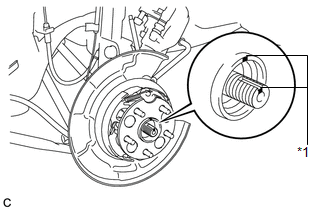

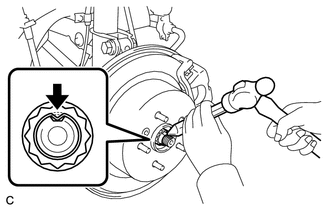

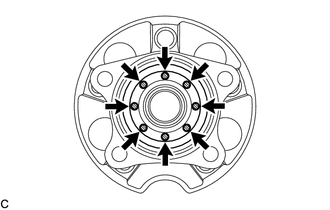

1. INSTALL REAR AXLE HUB AND BEARING ASSEMBLY

(a) Apply a total of 0.1 to 0.3g (0.00353 to 0.0105 oz.) of Toyota Body Grease W to the 8 areas shown in the illustration.

Text in Illustration

Text in Illustration

.png) |

Toyota Body Grease W |

|

(b) Align the matchmarks on the rear drive shaft assembly and the rear axle hub and bearing assembly. Text in Illustration

NOTICE: Do not rotate the rear drive shaft. |

|

|

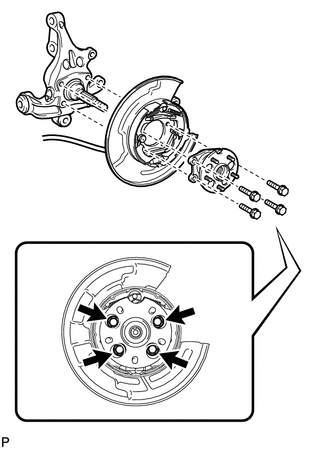

(c) Install the parking brake assembly and the rear axle hub and bearing assembly with the 4 bolts. Torque: 80 N·m {816 kgf·cm, 59 ft·lbf} NOTICE: Do not twist the parking brake cable assembly when installing it. |

|

2. INSTALL REAR AXLE SHAFT NUT

|

(a) Clean the threaded parts on the rear drive shaft assembly and a new rear axle shaft nut using a non-residue solvent. NOTICE:

|

|

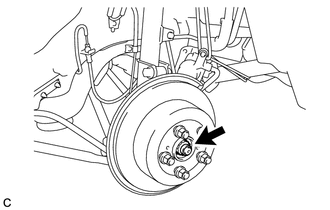

(b) install the rear disc with the 5 hub nuts.

(c) While applying the parking brakes, temporarily install the new rear axle shaft nut.

Torque:

294 N·m {2998 kgf·cm, 217 ft·lbf}

NOTICE:

Stake the nut after inspecting for looseness and runout in the following steps.

(d) Remove the 5 hub nuts and the rear disc.

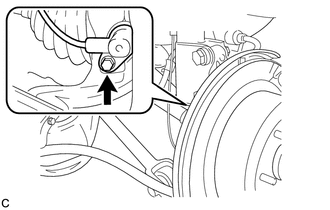

3. INSTALL REAR SPEED SENSOR

|

(a) Install the rear speed sensor to the rear axle carrier sub-assembly with the bolt. Torque: 8.5 N·m {87 kgf·cm, 75 in·lbf} NOTICE:

|

|

4. INSPECT REAR AXLE HUB BEARING LOOSENESS

.gif)

5. INSPECT REAR AXLE HUB RUNOUT

.gif)

6. INSTALL REAR DISC

.gif)

7. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

.gif)

8. STAKE REAR AXLE SHAFT NUT

|

(a) Using a chisel and a hammer, stake the rear axle shaft nut. |

|

9. INSTALL REAR WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

10. CHECK FOR SPEED SENSOR SIGNAL

(a) Check for the speed sensor signal (See page

.gif) ).

).

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR W ...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPAR ...

Other materials about Toyota Venza:

Precaution

PRECAUTION

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following systems after the cable is reconnected.

System Name

See Procedure

Back Door Closer System

...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is output during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" in the DTC chart.

Inspect the fuses and relays before troub ...

Light bulbs

You may replace the following bulbs yourself. The difficulty level of replacement

varies depending on the bulb. If necessary bulb replacement seems difficult to perform,

contact your Toyota dealer.

For more information about replacing other light bulbs, c ...

0.1222