Toyota Venza: Installation

INSTALLATION

PROCEDURE

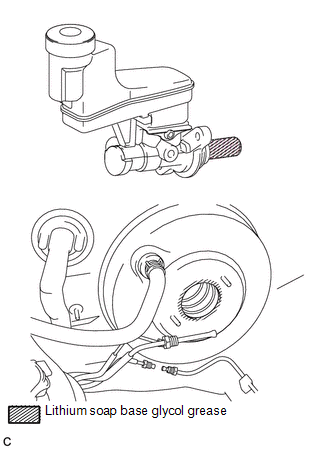

1. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

NOTICE:

When install a new brake master cylinder sub-assembly, remove the protectors from the piston and outlet ports.

(a) Install a new O-ring to the brake master cylinder sub-assembly.

|

(b) Apply a light layer of lithium soap base glycol grease to the entire circumference of the brake master cylinder sub-assembly and inner surface of the brake booster assembly as shown in the illustration. |

|

|

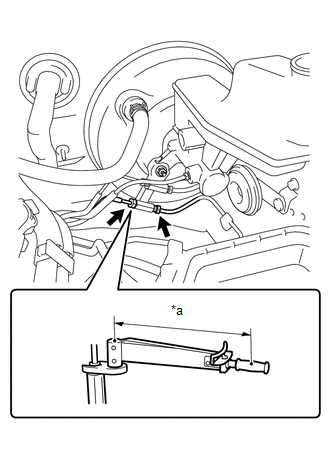

(c) Install the brake master cylinder sub-assembly and front brake tube way with the 2 nuts. Torque: 13 N·m {130 kgf·cm, 9 ft·lbf} NOTICE:

|

|

|

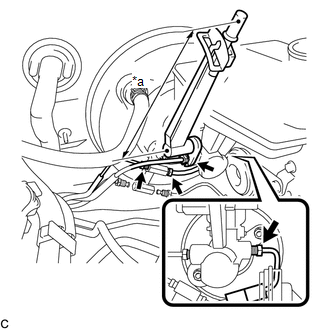

(d) Using a union nut wrench, connect the 2 brake lines and install the No. 1 front brake tube to the brake master cylinder sub-assembly. Text in Illustration

Torque: Specified Tightening Torque : 20 N·m {199 kgf·cm, 14 ft·lbf} NOTICE:

HINT:

|

|

|

(e) Using a union nut wrench, connect the 2 brake lines to the front brake tube way. Text in Illustration

Torque: Specified Tightening Torque : 15 N·m {155 kgf·cm, 11 ft·lbf} NOTICE:

HINT:

|

|

|

(f) Connect the connector and engage the clamp. |

|

2. FILL RESERVOIR WITH BRAKE FLUID

.gif)

3. BLEED BRAKE MASTER CYLINDER

.gif)

4. BLEED BRAKE LINE

.gif)

5. INSPECT FOR BRAKE FLUID LEAK

6. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

7. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

8. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 1AR-FE)

.gif)

9. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 2GR-FE)

.gif)

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from the booster by depressing the brake pedal several times.

Then remove the brake master cylinder from the brake booster.

PROCEDURE

...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY

(a) Apply a light layer of lithium soap base glycol grease to the entire circumference

of 2 new brake master cylinder rese ...

Other materials about Toyota Venza:

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU (Transmitter)

Receiving ECU (Receiver)

Signal

Line

Certification ECU

(Smart key ECU assembly)

Main body ECU

(Driver side junc ...

Seat Belt Buckle Switch LH Circuit Malfunction (B1656/38)

DESCRIPTION

The seat belt buckle switch LH circuit consists of the center airbag sensor assembly

and front seat inner belt assembly LH.

DTC B1656/38 is stored when a malfunction is detected in the seat belt buckle

switch LH circuit.

DTC No.

...

System Description

SYSTEM DESCRIPTION

CAUTION:

If using a pacemaker, be sure to read the manual of the pacemaker before using

the key, as the radio waves of the key may affect the pacemaker.

1. SMART KEY SYSTEM DESCRIPTION

(a) In addition to conventional mechanical key and ...

0.1317

.png)

.png)