Toyota Venza: Inspection

INSPECTION

PROCEDURE

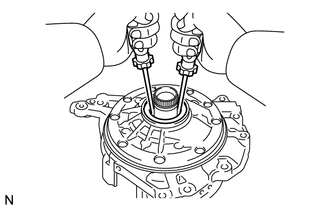

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

|

(a) Turn the drive gear with 2 screwdrivers and make sure that it rotates smoothly. NOTICE: Be careful not to damage the oil seal lip. |

|

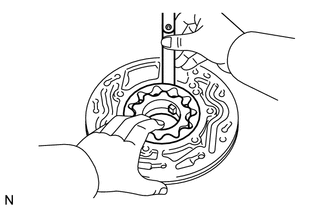

2. INSPECT CLEARANCE OF FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

|

(a) Push the driven gear to one side of the body. |

|

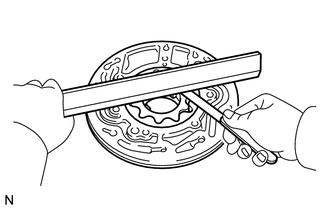

(b) Using a feeler gauge, measure the clearance.

Standard clearance:

0.08 to 0.15 mm (0.00315 to 0.00590 in.)

Maximum clearance:

0.15 mm (0.00590 in.)

If the clearance is greater than the maximum, replace the oil pump body sub-assembly.

|

(c) Using a straightedge and feeler gauge, measure the side clearance of both gears. Standard side clearance: 0.025 to 0.04 mm (0.000984 to 0.00157 in.) Maximum side clearance: 0.04 mm (0.00157 in.) Drive Gear Thickness

|

|

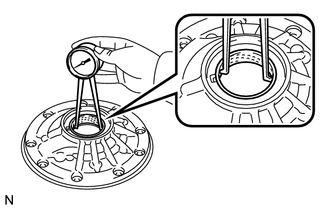

3. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

|

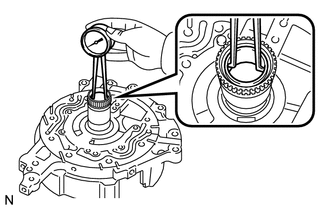

(a) Using a dial indicator, measure the inside diameter of the oil pump body bushing. Standard inside diameter: 43.113 to 43.138 mm (1.6974 to 1.6983 in.) Maximum inside diameter: 43.188 mm (1.7003 in.) If the inside diameter is greater than the maximum, replace the oil pump body sub-assembly. |

|

4. INSPECT STATOR SHAFT ASSEMBLY

|

(a) Using a dial indicator, measure the inside diameter of the oil pump body bushing. Standard inside diameter: 22.500 to 22.526 mm (0.8858 to 0.8868 in.) Maximum inside diameter: 22.570 mm (0.8886 in.) If the inside diameter is greater than the maximum, replace the oil pump body sub-assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

2. REMOVE STATOR SHAFT ASSEMBLY

(a) Using a "TORX" wrench (T30), remove the 16 bolts and stator s ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT OIL PUMP OIL SEAL

(a) Using SST and a hammer, install a new oil seal to the oil pump body.

SST: 09350-32014

09351-32140

Oil seal driven in ...

Other materials about Toyota Venza:

Headlight Signal Circuit

DESCRIPTION

The headlight leveling ECU assembly detects the low beam headlights status.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

First check that the low beam headlights operate normally.

PROCEDURE

1.

CHECK HARNESS AND CON ...

Test Mode Procedure

TEST MODE PROCEDURE

1. ENTER TEST MODE (SIGNAL CHECK MODE)

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Check that the tire pressure warning light comes on for 3 seconds and then

goes ...

If the battery is discharged

The following procedures may be used to start the engine if the battery is

discharged.

You can call your Toyota dealer or qualified repair shop.

If you have a set of jumper (or booster) cables and a second vehicle with a 12

volt battery, you can jump sta ...

0.1578