Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

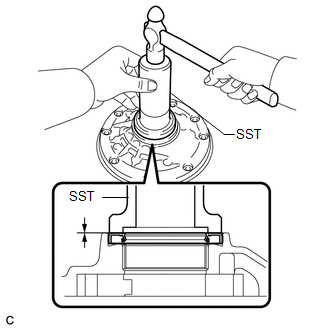

1. INSTALL FRONT OIL PUMP OIL SEAL

|

(a) Using SST and a hammer, install a new oil seal to the oil pump body. SST: 09350-32014 09351-32140 Oil seal driven in depth: -0.25 to 0.25 mm (-0.00984 to 0.00984 in.) |

|

(b) Coat the lip of the oil seal with MP grease.

2. INSTALL FRONT OIL PUMP BODY O-RING

|

(a) Coat a new O-ring with ATF and install it to the oil pump body. NOTICE: Ensure that the O-ring is not twisted. |

|

3. INSTALL FRONT OIL PUMP DRIVEN GEAR

|

(a) Coat the front oil pump driven gear with ATF and install it to the oil pump body with the marked side up. |

|

4. INSTALL FRONT OIL PUMP DRIVE GEAR

|

(a) Coat the front oil pump drive gear with ATF, and install it to the oil pump body with the marked side up. |

|

5. INSTALL STATOR SHAFT ASSEMBLY

|

(a) Align each knock pin of the stator shaft with the holes in the oil pump body and install the stator shaft to the oil pump body. |

|

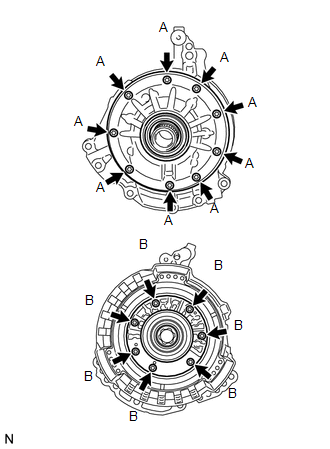

(b) Using a "TORX" socket (T30), install the 16 bolts.

Torque:

9.3 N·m {95 kgf·cm, 82 in·lbf}

| - | Bolt Length |

|---|---|

| Bolt A |

14 mm (0.551 in.) |

| Bolt B |

26 mm (1.02 in.) |

6. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

(a) Turn the drive gear with 2 screwdrivers and make sure that it rotates

smoothly.

NOTICE:

Be careful ...

Other materials about Toyota Venza:

Blind Spot Mirrors

The Blind Spot Mirrors increase the view of surrounding area to assist the driver

when checking surrounding area before changing lanes.

1. Blind Spot Mirror field of view

2. Main mirror field of view

- Mirror angle can be adjusted when

►V ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Television Camera

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE REAR WIPER ARM HEAD CAP

3. REMOVE REAR WIPER ARM AND BLADE ASSEMBLY

4. REMOVE REAR WIPER MOTOR GROMMET

5. ...

0.1541

.png)

.png)

.png)