Toyota Venza: ECU Power Source Circuit

DESCRIPTION

This circuit provides power for main body ECU (driver side junction block assembly) operation.

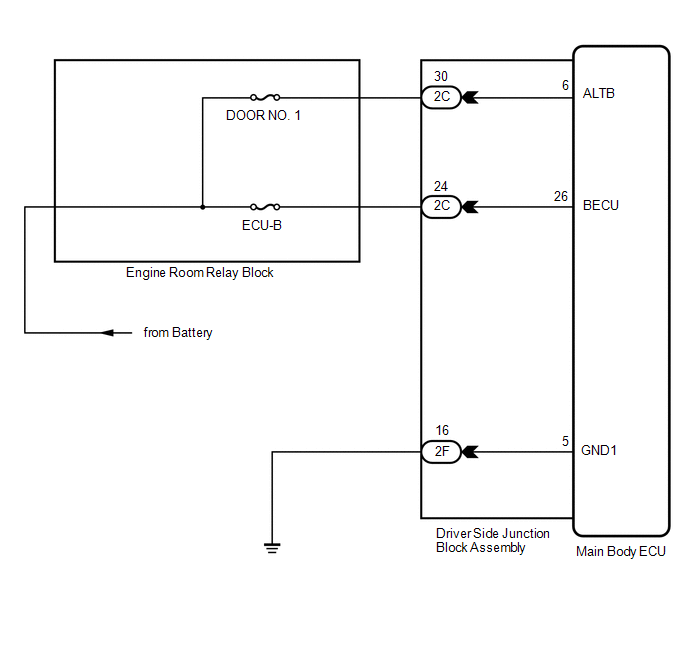

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK DRIVER SIDE JUNCTION BLOCK ASSEMBLY (MAIN BODY ECU (POWER SOURCE)) |

|

(a) Disconnect the 2C driver side junction block assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2C-24 - Body ground |

Always |

11 to 14 V |

|

2C-30 - Body ground |

Always |

11 to 14 V |

|

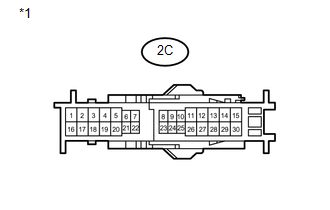

*1 |

Front view of wire harness connector (to Driver Side Junction Block Assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (DRIVER SIDE JUNCTION BLOCK ASSEMBLY - BODY GROUND) |

|

(a) Disconnect the 2F driver side junction block assembly connectors. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2F-16 - Body ground |

Always |

Below 1 Ω |

|

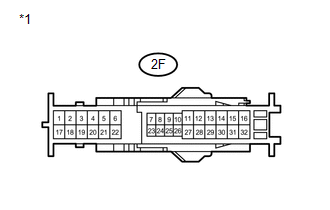

*1 |

Front view of wire harness connector (to Driver Side Junction Block Assembly) |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Security Indicator Light Circuit

Security Indicator Light Circuit

DESCRIPTION

Even when the theft deterrent system is in the disarmed state, the security indicator

blinks due to a signal output from the immobiliser system. The security indicator

blinks continuo ...

Other materials about Toyota Venza:

Only Wireless Control Function is Inoperative

DESCRIPTION

The door control receiver receives signals from the transmitter and sends these

signals to the main body ECU. The main body ECU then controls all doors by sending

lock/unlock signals to each door, and sends hazard flasher relay signals to the ...

Power Mirror Control System(w/o Memory)

Parts Location

PARTS LOCATION

ILLUSTRATION

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symptoms are l ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY

3. ...

0.1567

.gif)