Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT LUMBAR SUPPORT ADJUSTER ASSEMBLY

(a) Check operation of the lumbar support adjuster.

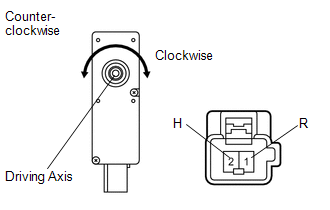

(1) Check if the lumbar support adjuster moves smoothly when the battery is connected to the lumbar support adjuster motor connector terminals.

OK:

|

Measurement Condition |

Operation Direction |

|---|---|

|

Battery positive (+) → 1 (R) Battery negative (-) → 2 (H) |

Clockwise |

|

Battery positive (+) → 2 (R) Battery negative (-) → 1 (H) |

Counterclockwise |

If the result is not as specified, replace the lumbar support adjuster assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT SEAT HEADREST ASSEMBLY

2. REMOVE FRONT SEAT REAR OUTER TRACK COVER

3. REMOVE FRONT SEAT REAR INNER TRACK COVER

4. REMOVE FRONT SEAT ASSEMBLY

5. REMOVE ...

Other materials about Toyota Venza:

Wireless Transmitter Memory Function does not Operate

DESCRIPTION

With the ignition switch off and the driver door closed, pressing the manual

lock or unlock switch on the power window regulator master switch assembly while

holding a seat memory switch (M1 switch or M2 switch) will register the transmitter

...

Power Source Circuit

DESCRIPTION

1. w/o Multi-information Display

(a) This circuit is the power source circuit for the accessory meter assembly.

This circuit provides two types of power sources; one is a constant power source

mainly used as a backup power source, and the oth ...

Pressure Sensor Circuit (B1423/23)

DESCRIPTION

This DTC is output when refrigerant pressure on the high pressure side is extremely

low (190 kPa (1.9 kgf/cm2, 28 psi) or less) or extremely high (3140 kPa (32.0 kgf/cm2,

455 psi) or more). The A/C pressure sensor is installed on the high pres ...

0.1555